Bokamoso ba ho Sterilization ea Metsi Ntle le Li-additives

Indastering e ntseng e tsoela pele ka potlako ea lijo le lino, bareki ba ntse ba ela hloko haholoanyane ka lihlahisoa tseo ba li jang, haholo-holo mabapi le metsoako e sebelisoang. Har'a mekhoa ea bohlokoa ka ho fetisisa ke tlhokahalo e ntseng e eketseha ea lijo le lino tse se nang metsoako ea maiketsetso, li-preservative le metsoako e meng ea maiketsetso. Phetoho ena e lebisitse ho tsoelopele e kholo ho hloekisoa ha metsi le mahlale a ho atolosa lishelefo, haholoholo molemong oa ho fihlela lihlahisoa tse tšoarellang nako e telele ntle le tlhoko ea li-additives. Empa re se re fihlile boholeng bo bokae sebakeng see?

Ho Utloisisa Phephetso: Paballo ea Tlhaho Ntle le Lieketsa

Bothata ba ho boloka lihlahisoa tsa lijo tse nang le metsi ntle le ho itšetleha ka li-preservative tsa maiketsetso ha li ncha. Ka lilemo tse ngata, indasteri ea lijo e ntse e thatafalloa ke ho fumana mekhoa e eketsang bophelo ba sethala ha e ntse e boloka boleng ba sehlahisoa, polokeho le botsitso ba phepo e nepahetseng. Mekhoa e tloaelehileng ea ho boloka, joalo ka tšebeliso ea li-additives tsa lik'hemik'hale kapa pasteurization, hangata e fetola tatso, sebopeho, kapa boemo ba phepo ea sehlahisoa, e leng se sa lokelang bareki ba kajeno ba hlokolosi haholoanyane.

Ho thibela metsi, ho kenyelletsang ts'ebetso ea ho tlosa likokoana-hloko tse kotsi marong ho eketsa nako ea bophelo, ke e 'ngoe ea mahlale a bohlokoa a bileng le boqapi bo boholo lilemong tsa morao tjena. Leha ho le joalo, katleho mona ha se feela ho ntlafatsa ts'ebetso ea sterilization empa ho etsa joalo ntle le ho senya boleng ba tlhaho ba sehlahisoa, haholo-holo bakeng sa lihlahisoa tse ratoang joalo kamoriana oa tamati, mango puree, lemetsi a kokonate.

Ho phahama ha Litheknoloji tsa Sejoale-joale tsa Sterilization Liquid

Mekhoa ea sejoale-joale ea sterilization ea metsi, haholoholoMocheso o Phahameng ka ho Fetisisa (UHT)sebetsa leente e tobileng ea mouoane, e entse hore ho khonehe ho thibela lihlahisoa ka mocheso o phahameng haholo ka nako e khutšoanyane haholo. Ts'ebetso ena e potlakileng ea ho futhumatsa le ho pholisa e lumella ho timetsoa ha libaktheria le likokoana-hloko tse ling, ho lelefatsa bophelo ba sethala ntle le tlhoko ea li-preservatives tse ekelitsoeng. Mekhoa ena e fetoha ea bohlokoa ka ho khetheha liindastering moo ho boloka tatso ea tlhaho le limatlafatsi tsa lihlahisoa tse kangmoriana oa tamati, mango puree, lemetsi a kokonateke ntho e tlang pele.

UHT, mohlala, e sebelisoa haholo tlhahiso ea lebese le lero la litholoana, empa ts'ebeliso ea eona ho lihlahisoa tse kangmela ea tlhahiso ea tomatelemela ea tlhahiso ea mango pureee boetse e ipakile e sebetsa. Molemo o ka sehloohong oa theknoloji ena ke bokhoni ba eona ba ho boloka tatso le limatlafatsi tsa sehlahisoa ha u ntse u netefatsa tšireletso ea likokoana-hloko. Ha thekenoloji ea UHT e ntse e tsoela pele, e se e sebetsa hantle le ho sebetsa hantle ho boloka litšobotsi tsa tlhaho tsa mokelikeli, ebang ke monate oamango pureekapa boleng bo khathollang bametsi a kokonate.

Tlhahiso e 'ngoe ea ho etsa sterilization ea metsi keho thibela ente ea mouoane ka kotloloho. Mokhoa ona o sebelisa mouoane ho futhumatsa mokelikeli kapele, ho etsa bonnete ba hore o thibela metsi ha o ntse o fokotsa nako eo mokelikeli o leng mocheso o phahameng. Sena se thusa ho boloka tatso le boleng ba phepo ea sehlahisoa, 'me se molemo ka ho khetheha bakeng salikhoele tsa tlhahiso ea metsi a kokonate, moo ho boloka bocha le lintho tsa tlhaho tsa mokelikeli ho leng bohlokoa bakeng sa boipiletso ba bareki.

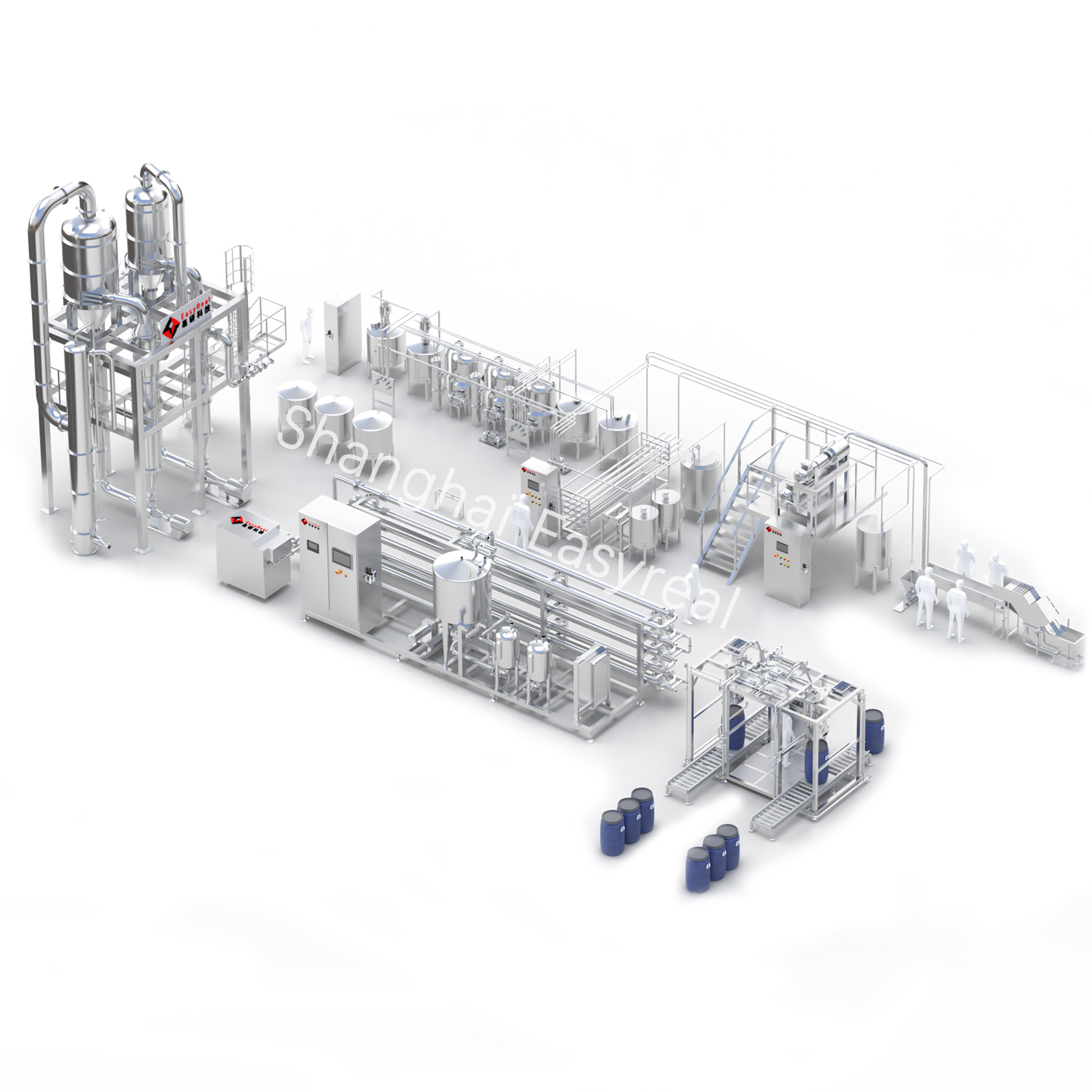

Bohlokoa baMechini ea Lab UHTleLimela tsa Pilot

Le ha mahlale a ho thibela metsi a kang UHT le ente e tobileng ea mouoane e entse tsoelo-pele e kholo, bahlahisi ba hloka ho netefatsa hore mahlale ana a ntlafatsoa ka botlalo pele a fetela mehala e meholo ea tlhahiso. Ke hona moomechine ea lab UHTlelimela tsa lifofanebapala karolo ea bohlokoa, haholo maemong a mela e ikhethileng ea tlhahiso joalo ka eamoriana oa tamati, mango puree, lemetsi a kokonate.

- Mechini ea Lab UHT: Mechini ena e lumella bahlahisi hore ba leke lits'ebetso tsa UHT ka tekanyo e nyane, ba pheta-pheta maemo a tlhahiso e kholo. Mohlala, ho leka liparamente tse fapaneng tsa UHT homoriana oa tamati or mango pureee lumella bahlahisi ho lokisa tšebetso hantle ho etsa bonnete ba hore lihlahisoa tsena li boloka tatso ea tsona e monate le masela ha li ntse li fihlella shelofo e hlokahalang. Hoa tšoana le hometsi a kokonate, moo mocheso le taolo ea nako li leng bohlokoa bakeng sa ho boloka litšoaneleho tse ncha tsa tlhaho tsa seno.

- Limela tsa Pilot: Limela tsa liteko li sebetsa e le borokho lipakeng tsa liteko tsa laboratori le tlhahiso e felletseng. Ba fana ka maemo a nnete a ho leka mekhoa e mecha ea ho thibela likokoana-hloko, libopeho le mekhoa ea tlhahiso ka tekanyo e nyane empa e kholo ho feta litlhophiso tsa lab. Mohlala, limela tsa liteko li lumella bahlahisi ho lekola ho ata ha mekhoa e mecha ea ho thibela likokoana-hloko holine ea tlhahiso ea tomate sauce or mola oa tlhahiso ea mango puree. Sena se thusa ho ntlafatsa lits'ebetso le ho netefatsa hore ha theknoloji e ntse e eketseha, e tla boloka boleng bo ts'oanang le ts'ebetso e ts'oanang, ebang ke bakeng sa lihlopha tse nyenyane kapa tlhahiso ea bongata.

Ntle le mechini ea lab ea UHT le limela tsa lifofane, kotsi ea ho tsetela ho mahlale le lits'ebetso tse sa netefatsoang e eketseha haholo. Mehaho ena e fana ka lintlha tsa bohlokoa tse hlokahalang ho etsa liqeto tse nepahetseng mabapi le ho eketsa tlhahiso, ho fokotsa menyetla ea liphoso tse bitsang chelete e ngata le ho netefatsa hore sehlahisoa sa ho qetela se kopana le maemo a tšireletso le litebello tsa bareki.

Tsoelo-pele: Re Hokae Hona Joale?

Potso ea 'nete ke hore: ke tsoelo-pele e kae e entsoeng ho thibela metsi le katoloso ea bophelo ba lishelefo ntle le li-additives? Karabo ke hore indasteri ea lijo le lino e entse tsoelo-pele e kholo, empa ho ntse ho e-na le mathata a lokelang ho hlola.

- Mekhoa e Ntlafetseng ea ho Sterilization: Tsoelo-pele ho UHT le theknoloji e tobileng ea ente ea mouoane e entse hore ho khonehe ho lelefatsa sethala sa nako ea lino tse metsi ntle le ho fetola tatso ea tsona ea pele kapa lijo tse nang le phepo. Theknoloji ena e 'nile ea ntlafatsoa khafetsa ho fana ka ts'ebeliso e ntle ea matla, linako tsa ts'ebetso e potlakileng, le taolo e nepahetseng haholoanyane holim'a mocheso, tseo kaofela li tlatsetsang sehlahisoa se phahameng.

- Likhetho tsa Bareki Ho Bopa Boiqapelo: Bareki ba kajeno ba tseba ho feta leha e le neng pele ka se kenang lijong le linong tsa bona. Phetoho ena ea khetho ea bareki e lebisitse tlhokomelong e eketsehileng homekhoa ea ho boloka tlhahotse qobang tšebeliso ea lik’hemik’hale tsa maiketsetso. Tlhokahalo ena e tsamaisitse nts'etsopele ea lits'ebetso tse ncha, tse sebetsang haholoanyane tsa ho thibela likokoana-hloko.

- Scaling for Mass Production: Le hoja boholo ba tsoelo-pele ena e atlehile ka tekanyo e nyenyane, bokhoni ba ho lekanya mekhoa ena bakeng sa tlhahiso ea bongata ntle le ho lahleheloa ke bokhoni kapa boleng ba sehlahisoa e ntse e le sebaka se tsoelang pele sa tsoelo-pele. Leha ho le joalo, indasteri e hatela pele ho feto-fetola litheknoloji tsena tse tsoetseng pele hore li sebelisoe litsing tse kholo ha li ntse li boloka boemo bo ts'oanang ba boleng ba sehlahisoa, ebang ke bakeng samoriana oa tamati, mango puree, kapametsi a kokonatemela ea tlhahiso.

- Ho Boloka Botšepehi ba Phepo: Mohlomong ntho ea bohlokoa ka ho fetisisa lilemong tsa morao tjena ke bokhoni ba ho boloka boleng ba phepo ea lijo tse metsi. Mekhoa ea morao-rao ea sterilization e entsoe ka sepheo sa ho netefatsa hore livithamini, liminerale le li-antioxidants lihlahisoa tse kang.lero la litholoana, li-tomate sauces, lemetsi a kokonatelula u tiile, ho sa tsotellehe ts'ebetso ea sterilization.

Bokamoso ba ho Sterilization ea Metsi Ntle le Li-additives

Ha re sheba pele, ho hlakile hore bokamoso ba ho thibela metsi ka metsi bo itšetlehile ka mekhoa e tsoetseng pele le e sebetsang hantle. Ha lipatlisiso li ntse li tsoela pele, re ka lebella ho bona ntlafatso ea taolo ea ts'ebetso, matla a matla, le bokhoni ba ho boloka eseng feela polokeho ea sehlahisoa empa litšoaneleho tsa sona tsa mantlha. Ho ka 'na ha boela ha e-ba le keketsehomekhoa e meng, e seng ea ho boloka mocheso, joalo ka high-pressure processing (HPP), e ka tlatsanang kapa esita le ho nkela sterilization ea setso e thehiloeng mocheso lits'ebetsong tse itseng.

Bakeng sa Baetsi, Phephetso e Letse ho Balancing Cutting-Edge Technologies

Bakeng sa bahlahisi, phephetso e tla ba ho leka-lekanya mekhoa ena ea morao-rao ea morao-rao le litebello tsa bareki bakeng sa ho khoneha, ho fumaneha le ho tšoarella. Ha tlhoko ea bareki ea lihlahisoa tse se nang litlatsetso e ntse e hola, ba ka ntlafatsang tsoelo-pele ena ea ho thibela metsi ba tla ba ka pele ho mehla e mecha ea tlhahiso ea lijo le lino - e shebaneng le boleng, polokeho le paballo ea tlhaho.

Qetello

Qetellong, ho entsoe tsoelo-pele e kholo ho sterilization ea metsi le theknoloji ea katoloso ea sethala ntle le tlhoko ea li-additives. Litheknoloji tse kang ts'ebetso ea UHT le ente e tobileng ea mouoane li entse hore ho khonehe ho boloka metsi ka katleho ha ho ntse ho bolokoa litatso le limatlafatsi tsa bona tsa tlhaho. Karolo eamechine ea lab UHTlelimela tsa lifofanelitekong, ho hloekisoa, le ho phahamisa mekhoa ea theknoloji ho bohlokoa bakeng sa ho netefatsa hore mekhoa e mecha ea ho thibela likokoana-hloko e ka kopanngoa ka mokhoa o sireletsehileng le ka katleho tlhahisong e kholo. Hore na ke tlhahiso eamoriana oa tamati, mango puree, kapametsi a kokonate, lintlafatso tsena tsa ho thibela metsi ka metsi li thusa bahlahisi ho fihlela tlhoko e ntseng e hola ea bareki bakeng sa lihlahisoa tsa boleng bo holimo, tse se nang litlatsetso. Ha mahlale ana a ntse a tsoela pele ho fetoha, re se re le mothating oa nako e ncha ea tlhahiso ea lijo le lino e shebaneng le boleng, polokeho le paballo ea tlhaho.

Nako ea poso: Feb-12-2025