Industrial Jam Processing Line

This industrial jam production line can be configured for:

• Strawberry jam, blueberry jam, raspberry jam, apricot jam, peach jam, apple jam

• Citrus marmalade (orange/lemon peel applications)

• Mixed-fruit preserves and fruit spreads

• Smooth jam (no pieces) or jam with fruit pieces

• Industrial supply jam base for bakery, dairy, ice cream, and dessert manufacturers

Raw material options: fresh fruit, frozen fruit, fruit puree, fruit concentrate, blended fruit bases.

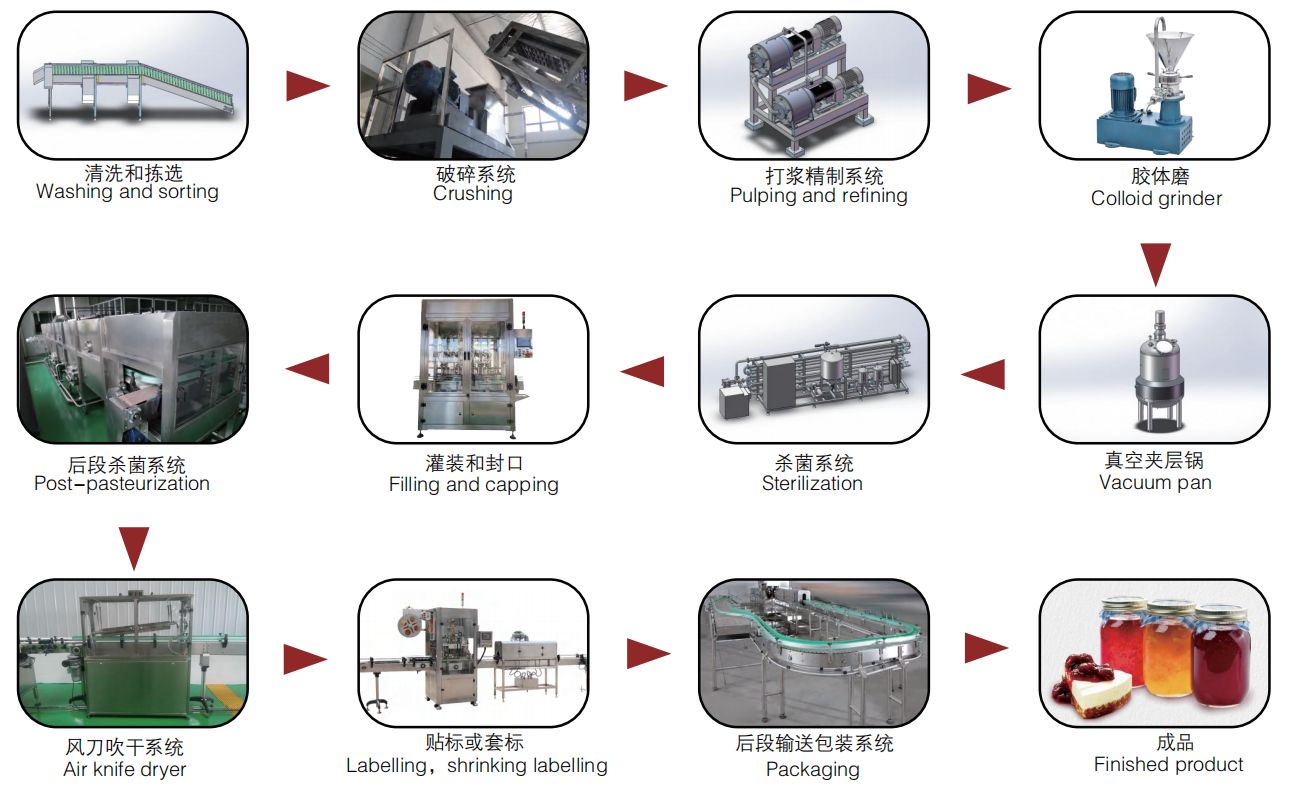

Route A: From Fresh Fruit (for seasonal fruit processing plants)

Receiving → washing→sorting → crushing → pre-heater-pulping and extraction & refining → vacuum dilution cooking→ optional homogenizer →sterilization→ filling and capping → conveyor and packaging

Route B: From Puree or Concentrate (for stable year-round production)

Puree/concentrate feeding →vacuum dilution cooking → standardization (°Brix/pH/solids)→ optional homogenizer→ sterilization(as required) → filling and packing

Which route fits best depends on fruit availability, SKU complexity, shelf-life strategy, and packaging choices.

1) Fruit Base Preparation (Yield + Texture Foundation)

Jam quality starts with the fruit base. This section is configured by fruit type to control:

• Seed/skin removal requirements

• Fiber and particle profile (mouthfeel, spreadability, gel behavior)

• Pulp yield and solids recovery

• Downstream process stability (less clogging, more consistent viscosity)

Why it matters: inconsistent fruit base means inconsistent jam—no matter how good the cooking step is.

2) Formulation & Blending (Repeatability Engine)

Industrial jam requires precise dissolution and dispersion:

• Sugar dissolution strategy (to reduce crystallization risks)

• Pectin/hydrocolloid dispersion options (to avoid lumps and “fish-eyes”)

• Acid dosing to lock pH into the gel window

• Optional flavor dosing and micro-ingredients management

• Mixing style selected for viscosity and particle sensitivity

This is where you “lock in” the recipe before concentration.

3) Vacuum Cooking / Concentration (Jam Quality Core)

Vacuum cooking is commonly selected for industrial jam because it supports:

• Lower boiling temperature for better flavor and color retention

• Efficient water removal to reach target °Brix

• Predictable viscosity and thermal history control

• Reduced risk of overcooking compared with atmospheric boiling (process-dependent)

Configuration options depend on your capacity and SKU changeover needs.

4) Product Stability & SterilizationHygiene Control (Shelf-Life Strategy)

Depending on your product, packaging, and distribution, a stability/hygiene section may include:

• Foaming/air reduction steps when required (appearance, oxidation control, filling stability)

• Thermal treatment selection to meet microbial targets (process depends on recipe and regulations)

• Hygienic transfer and temperature control into the filling section

This section is often what separates “works in the lab” from “works in the factory every day.”

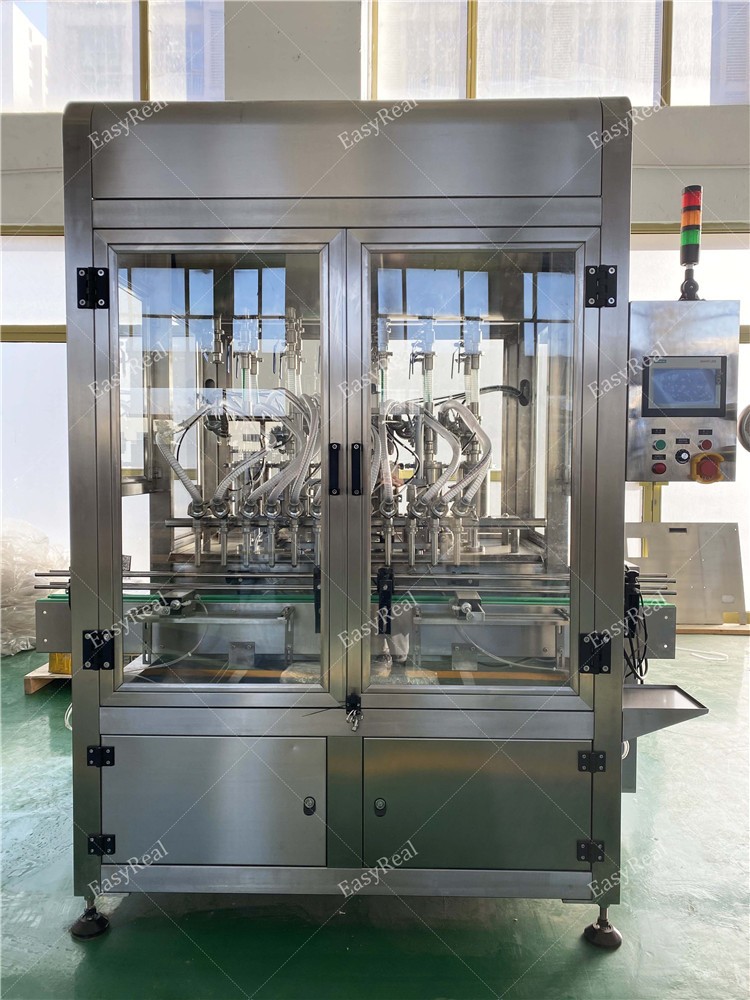

5) Filling & Packaging

Packaging format determines filling temperature, viscosity window, and cooling logic. Common options:

• Glass jar filling with twist-off / lug caps

• Cups/tubs for foodservice

• Pouches/sachets for portion packs (optional route)

If you already have filling/packing equipment, the line can be designed with clear interface points to integrate your existing assets.

A complete jam production line is typically built from these functional modules (configured to your project scope):

• Fruit receiving and preparation (optional)

• Crushing and pre-heating

• Ppulp extraction/refining

• Blending and formulation tanks

• Vacuum dilution cooking / concentration system

• HomogenizerOptional air/foam control (optionalwhen needed)

• SterilizationThermal stability/hygiene control section (when needed)

• Buffer tanks and sanitary transfer pumping

• Filling ,capping ,pasterization and packaging/capping and cooling

• CIP system

• -ready hygienic pipesing, valves, and instrumentation

• Siemens PLC + HMI recipe/setpoint management for repeatability

Designed for high-viscosity and sticky products

Jam is a high-solids, high-viscosity product. System sizing and agitation/transfer design are selected to handle:

• high sugar concentration

• fruit solids and particles

• viscosity changes during concentration

• stable flow for filling

Better control of key quality targets

The line is designed to control and document:

• °Brix target and concentration curve

• pH/acid window and gel stability logic

• viscosity range for filling and storage stability

• fruit particle size/fiber profile (by fruit type)

Hygienic design and efficient changeover

• Hygienic layout and sanitary fittings for food-grade operation

• CIP-ready structure to reduce downtime and support multi-SKU plants

• Clear access and cleaning considerations for sticky, sugar-rich products

To propose the correct configuration and sizing, please share:

1. Fruit type(s) and whether seeds/peels must be removed

2. Target products: jam, marmalade, preserves; smooth vs fruit pieces

3. Target °Brix, pH range, and desired texture/viscosity

4. Capacity target (kg/h or jars/h), daily run time, SKU count/changeover frequency

5. Packaging format and shelf-life requirements

6. Available utilities (steam, power, water, compressed air) and layout constraints

7. Existing equipment you want to keep (cookers/fillers/packers) for integration planning

Q1:What is the difference between a jam machine and a jam processing line?

A jam machine is a single unit (e.g., cooker). A jam processing line is the full system that includes fruit base preparation, dilution cooking,sterilization,and packaging integration.

Q2:Can the line handle jam with fruit pieces?

Yes. The process can be configured to protect piece integrity and improve stability (anti-float/sink) through gentle handling and viscosity tuning.

Q3:Why is vacuum cooking commonly used in industrial jam production?

Vacuum cooking can reduce boiling temperature and help preserve flavor/color while improving control of concentration and final texture (configuration-dependent).

Q4:Can you produce marmalade on the same line?

Yes. Marmalade often needs peel handling and tailored cooking/mixing control; the line can be configured accordingly.

Q5:Can the line support reduced-sugar jam?

It can, but reduced sugar requires tighter control of gel systems, solids, and pH. Provide your formulation targets so the process window can be engineered properly.

Q6:Can we integrate this with our existing filling line?

Yes. Many factories keep existing fillers/packers and upgrade the processing core. We define interface points (temperature window, viscosity range, sanitary transfer, CIP strategy) to integrate smoothly.