Pilot Multi-effect Falling Film Evaporation

The pilot scale Multi-effect Falling film evaporator completely completely simulated the industrial production sterilization in the laboratory, mainly used for concentration of solutions in dairy product industry, food industry, fruit juice industry, beverage, chemical industry, environmental protection industry, pharmaceutical industry, etc.

It is suitable for wide range of visidity, and widely used for concentration of fruit and vegetable juice, dairy, Chinese herbal medicine, western medicine, glucose, animal protein, plant protein, starch, oral liquid, chemical, health food, pigment, additives, monosodium glutamate, etc.

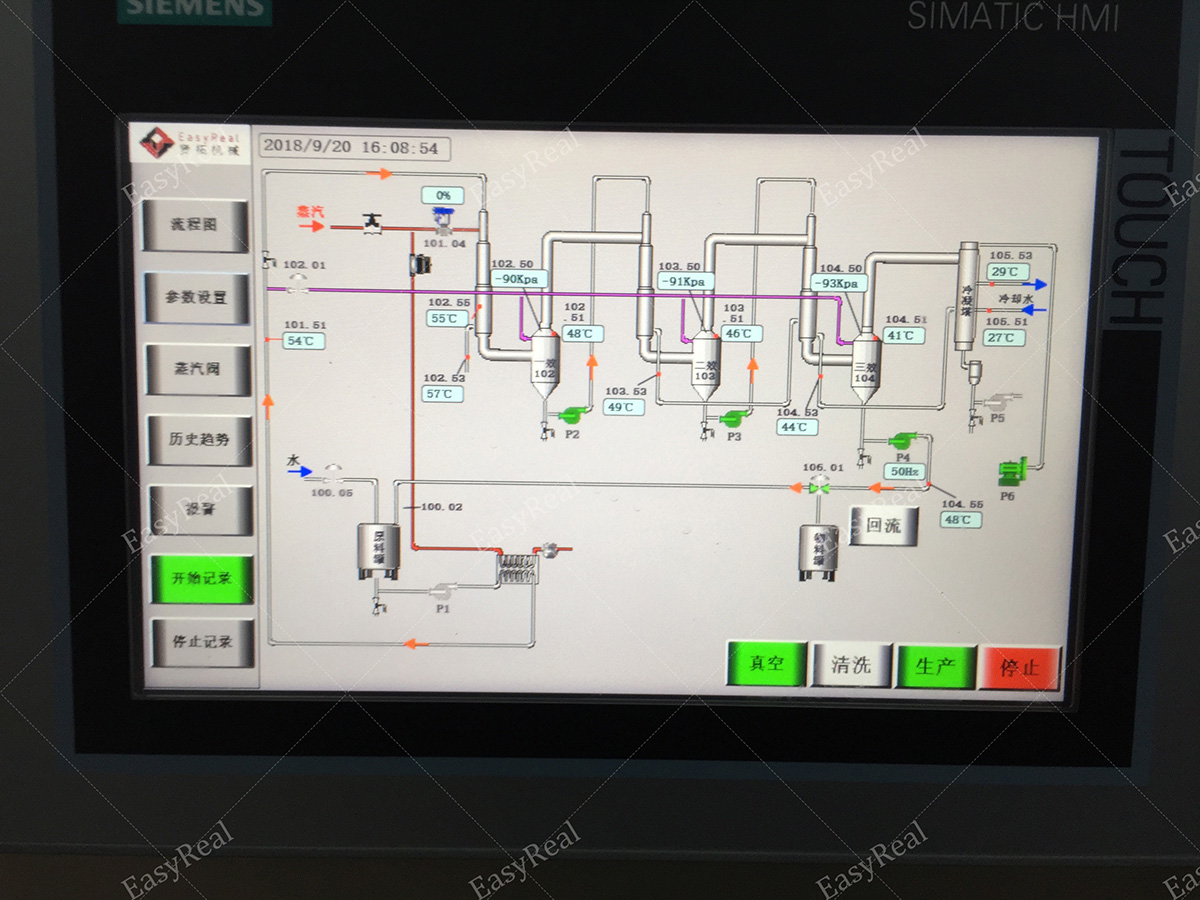

1. Independent Siemens control system.

2. Main structure is SUS304 stainless steel or SUS316L stainless steel.

3. Combined Italian technology and confirm to Euro-standard.

4. Running stably, high efficiency.

5. Low energy consumption.

6. High heat transfer coefficient.

7. High evaporation intensity.

8. Short flow passing time and high operating elasticity.

1. Realization of automatic control of material delivery and signal conversion.

2. High degree of automation, minimize the number of operators on the production line.

3. All electrical components are international first-class top brands, to ensure the stability and reliability of equipment operation;

4. In the process of production, man-machine interface operation is adopted. The operation and state of the equipment are completed and displayed on the touch screen.

5. The equipment adopts linkage control to automatically and intelligently respond to possible emergencies;

|

Name |

Pilot Double-Effect Falling film evaporator |

Pilot Triple-Effect Falling film evaporator |

Pilot Double-Effect Falling film evaporator |

|

Rated evaporation |

35L/H |

50L/H |

500 L/H |

|

Power: KW |

4.8KW |

5.5KW |

16KW |

|

Temperature Inlet: ℃ |

Room temperature |

Room temperature |

Room temperature |

|

Temperature outlet |

<50℃ |

<48 ℃ |

<48 ℃ |

|

Consumption of steam |

20G/H |

20 KG/H |

330KG/H |

|

Dimension:mm |

2400×1300×3000mm |

2900×1300×3000mm |

3600×2000×4800mm |

|

Above for reference, you have a wide choice depend on actual need. |

|||