Coconut Processing Line

This industrial line delivers high-volume coconut milk and water production for beverage and ingredient manufacturers.

Operators feed de-husked coconuts into the system, which cuts, drains, and separates water and pulp.

The milk section grinds and presses the kernel under controlled heating to release coconut cream.

Closed-loop sensors monitor pressure, temperature in every stage.

A central PLC system manages the heating, cooling, and sterilization phases.

Touch-screen HMIs let operators set temperature, pressure, check trends, and track production records.

Automated CIP cycles clean the stainless-steel contact surfaces after each shift without dismantling pipes or tanks.

All pipelines use sanitary 304/316 stainless steel, food-grade gaskets, and quick-clamp fittings for safe maintenance.

The layout follows modular logic.

Each section—preparation, extraction, filtration, standardization, sterilization, and filling—runs as an independent unit.

You can expand output or add new SKUs without stopping the main line.

As a result, factories get steady product quality with minimum downtime.

Industrial coconut milk processing plants serve multiple sectors:

• Beverage factories that bottle pure coconut water or flavored drinks.

• Food processors producing coconut cream for ice cream, bakery, and dessert bases.

• Export units packing UHT milk and water for global retail and HORECA markets.

• Ingredient suppliers serving dairy alternatives and vegan formulations.

Each factory faces tight audits on hygiene, label accuracy, and shelf life.

This line keeps records for temperature and batch data, helping you pass ISO and CE compliance checks with ease.

The automated valves and smart recipes reduce operator error, which means fewer customer complaints and steadier deliveries.

Coconut milk and water have unique risks.

They carry natural enzymes and fats that spoil fast when heated unevenly.

Viscosity changes quickly with temperature, therefore, if the processing is long, the raw materials need to be cooled quickly and stored at low temperatures to avoid rancidity caused by long processing.

This industrial production line uses a homogenizer to ensure an even distribution of the coconut milk fat.

Adopt Vacuum de-aeration removes air bubbles that cause oxidation and flavor loss.

Adopt Tubular UHT Sterilizer to ensure effective sterilization of products

Each tank has CIP spray balls to kill germs and remove fat residue after production.

The result is a clean, consistent output that retains the coconut’s white color and fresh aroma.

Start with your target output.

For example, an 8-hour shift at 6,000 L/h delivers ≈48 tons of coconut milk per day.

Choose the equipment capacity to match your market size and SKU mix.

Key parameters include:

• Heat-transfer area and vacuum range in the sterilizer.

• Type of agitator (scraper type for cream lines; high-shear for milk).

• Pipe diameters and valve manifolds that support automated CIP and quick changeovers.

• Filling method (aseptic bag, glass bottle, can, or PET).

We recommend a pilot verification before final layout to confirm heat balance and yield.

Our engineers then scale the system up to your industrial footprint and utility plan.

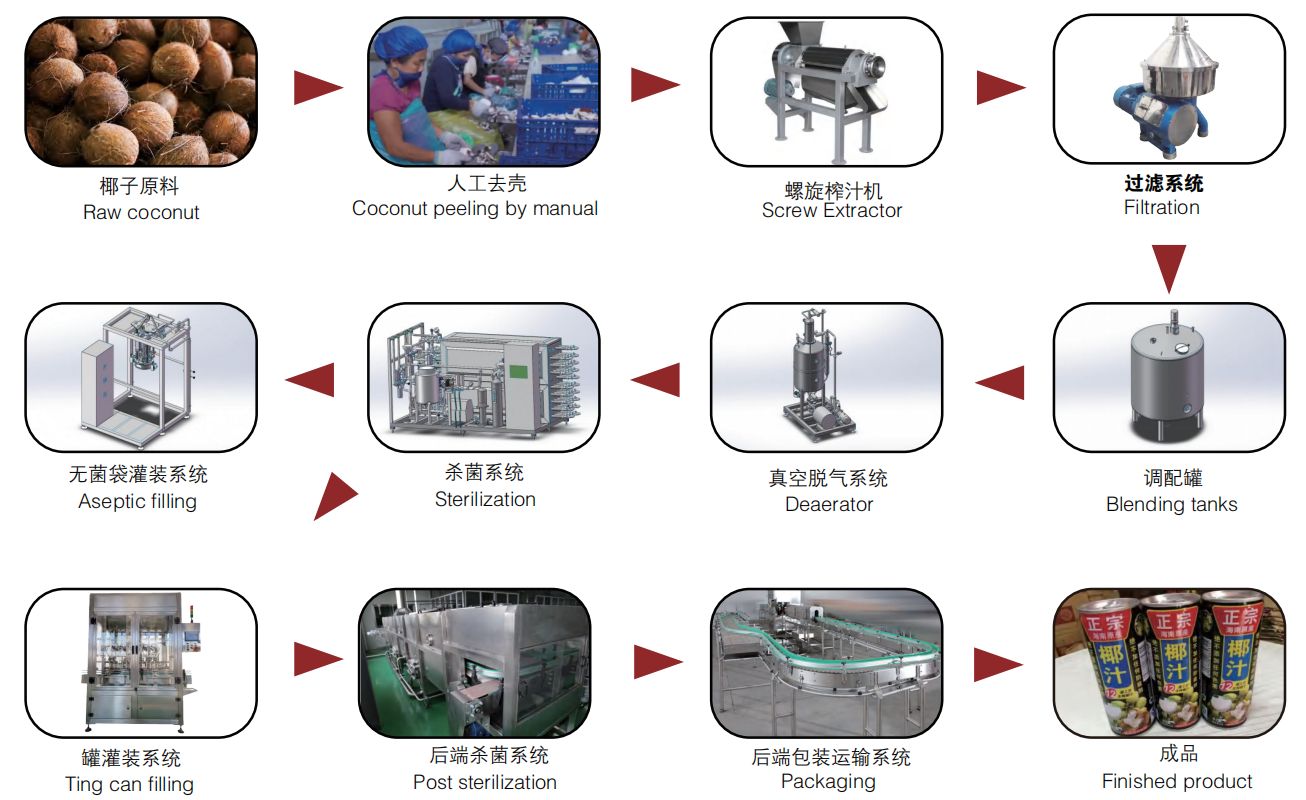

1. Raw Intake and Sorting

Workers load de-husked coconuts onto the feeding belt.

2. Cracking and Water Collection

The drilling machine opens holes in coconuts to extract water and collect it in a storage tank to avoid dust.

3. Kernel Peeling and Washing

The coconut meat is peeled, washed, and inspected for brown spots to maintain its natural white color.

4. Grinding and Pressing

High-speed mills crush the pulp into small particles, and a mechanical press extracts the coconut milk base.

5. Filtration and Standardization

Filters remove fibers and solids. Operators adjust fat content according to product specifications.

6. Homogenization and De-aeration

The milk passes through a high-pressure homogenizer and vacuum deaerator to stabilize texture and remove air. These units can be connected inline with the sterilizer for continuous homogenization and degassing.

7. Sterilization

Tubular sterilizers heat the milk to 142 °C for 2–4 seconds (UHT). Tube-in-tube sterilizers handle high-fat and high-viscosity cream lines.

8. Filling

The product cools to 25–30 °C and is filled using an aseptic filler.

9. CIP and Changeover

After each batch, the system runs a fully automated CIP cycle with alkaline and acid rinses to maintain hygiene and minimize downtime.

10. Final Inspection and Packing

Inline viscosity and Brix meters confirm consistency before cartoning and palletizing.

The same core process applies to coconut water production lines, with slight adjustments in filter grade and sterilization temperature to preserve natural electrolytes.

1. Coconut Drilling Machine and Water Collector

The drilling machine drills only a small hole in the coconut, keeping both water and kernel intact as much as possible.

A stainless-steel channel collects coconut water under a closed lid to prevent germs or dust.

This step protects natural flavor before the main extraction.

2. Coconut Milk Extraction Section

This section combines a grinder and a juice screw presser.

It breaks the coconut meat into small particles and uses the screw presser to squeeze coconut milk.

Compared with manual presses, it improves output by over 30% and keeps fat levels consistent.

3. Filtration and Centrifuge System for Coconut Water

A two-stage mesh filter removes large fibers in coconut water.

Then, a disc centrifuge separates water fractions, light oil, and impurities.

This separation improves coconut water product clarity.

4. Homogenizer

The coconut milk processing machine includes a high-pressure homogenizer to stabilize the emulsion.

At 40 MPa pressure, it breaks fat globules into micro-sized particles.

The milk stays smooth and doesn’t separate during storage.

This step is key to shelf stability in coconut drinks.

5. UHT Sterilizer

Choosing a tubular sterilizer or tube-in-tube sterilizer depends on the fluidity of the product.

Coconut water needs gentle heat to keep aroma; coconut cream needs fast heating to avoid burning.

PLC control keeps temperature within ±1 °C of the setpoint.

The energy recovery design of the tubular sterilizer helps clients reduce operation costs.

6. Aseptic Filling Machine

A coconut water processing machine finishes with a sterile filling system.

All product paths are made of SUS304 or SUS316L stainless steel.

It can work with the sterilizer together to realize inline CIP and SIP.

This ensures long shelf life without preservatives.

7. CIP Cleaning System

The automated CIP skid mixes water, alkali, and acid to clean tanks and pipes.

It runs defined cycles with flow, time, and temperature control.

Operators select recipes on the HMI and see real-time progress.

This process cuts cleaning time by 40% and keeps the entire coconut processing machine ready for the next batch.

Factories can run different coconut sources without changing the main line.

Fresh, frozen, or semi-processed coconuts all fit the same preparation section.

Sensors adjust speed and heating to match each material’s solids and oil content.

You can also run multiple output types:

• Pure coconut water in PET, glass, or tetra-pack.

• Coconut milk and cream for cooking or desserts.

• Concentrated coconut base for reconstitution in export markets.

• Blended drinks with fruit juice or plant protein.

Quick-change fittings and automatic valve manifolds reduce downtime during SKU changeovers.

That flexibility helps plants meet seasonal demand and improve production utilization.

The PLC and HMI system forms the brain of the entire line.

Operators can load predefined recipes for milk or water products and monitor each tank and pump in real time.

Smart features include:

• Central touchscreen with trend graphs and batch data.

• Role-based access for operators, supervisors, and maintenance staff.

• Ethernet link for remote monitoring and service support.

• Energy and water usage tracking for each batch.

Automatic interlocks keep unsafe actions from running, which protects both product and equipment.

The line stays stable across all shifts, even with limited operator training.

EasyReal supports your project from concept to commissioning.

Our team studies your product formula, packaging, and utility layout to design a balanced process.

We deliver:

• layout and P&ID design.

• Equipment supply, installation, and commissioning on-site.

• Operator training, spare parts, and remote service for your first production season.

Each coconut milk processing plant follows international hygiene and safety standards, with CE and ISO certifications.

Factories in Asia, Africa, and Latin America already run EasyReal lines producing thousands of liters per hour of coconut milk and water daily.

Contact us to discuss your target capacity and packaging style.

We’ll help you configure the right coconut processing machine to scale your production efficiently.