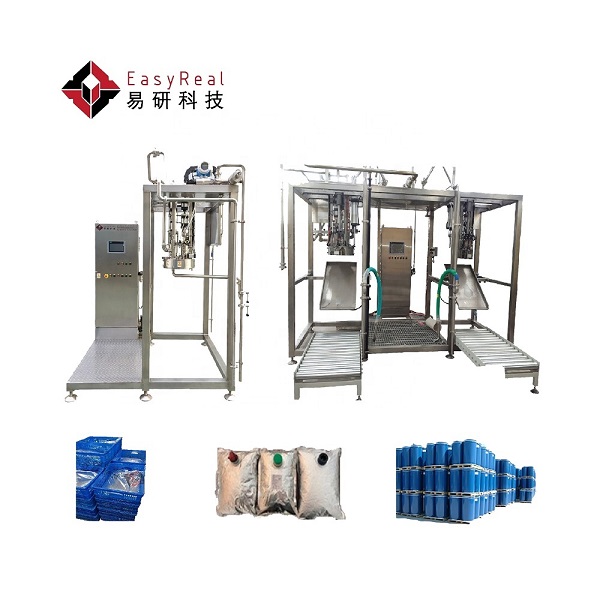

Aseptic Bags Filling Machine

The aseptic Bags Filling Machine is widely used in aseptic packaging of liquid foods, such as fruit and vegetable juice, juice concentrate, fruit and vegetable pulp, puree concentrate and paste, nature juice and pulp, etc. The natural fruit juice or pulp can be kept in the aseptic bags for more than one year under constant temperature, and the concentrated fruit juice or paste can be kept for more than two years.

And the Aseptic Bag Filling Plant is developed by confirming the most advanced technologies by EasyReal Tech, which is a National High-tech Enterprise, established in 2011, that specializes in manufacturing fruit and vegetable production lines and key equipment of various aseptic filling machines like Single Head Aseptic Bag Filling Machine, Double Head Aseptic Bag Filling Machine and Multi-head aseptic bag filling machines and so on.

- Why Aseptic Bag Filling Machine is the Flexible Solution?

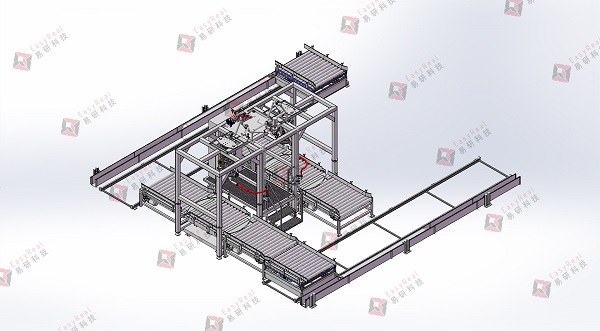

The same aseptic bag filling machine can achieve to fill concentrated and non-concentrated fruit purees and juices into aseptic bags of different sizes from 1L to 1000L, including flexible aseptic bag-in-box, 220 liters or 220L aseptic bag-in-drum, and 1000L aseptic bag in bin and wooden box through installing some easily additional devices.

- What is the double-head aseptic bag filling machine?

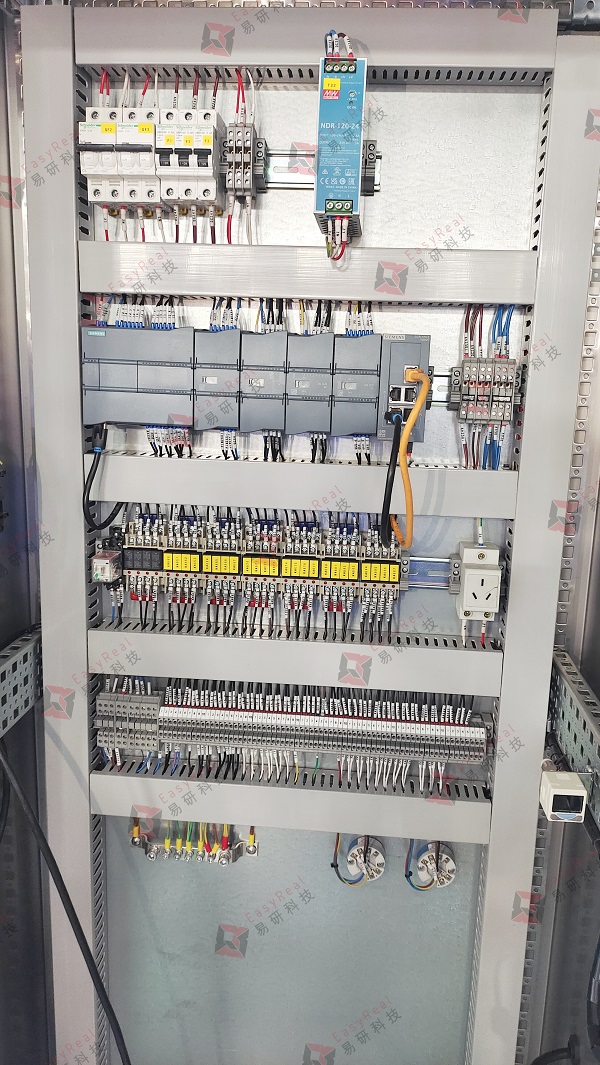

Double Head Aseptic Bag Filling Machine consists of two sterile filling heads with steam sterilization function, the temperature is controlled by a PT100 probe, the product dosage is measured by the Germany KROHNE/E+H flow meter or METTLER TOLEDO weighting system, and the instrument Integrated into the filling machine PLC. It can be used with the most common types of nozzles: 1-inch for juices and 2-inch for chopped or shredded products. Apart from the positioning of the aseptic bags, all other filling operations are automatically: controlled by the Germany Siemens Control System(Germany PLC and touch screen), which manages the sterilization, filling, CIP cleaning, and SIP sterilization processes, functional analysis, and error management. The panel is equipped with an HMI touchscreen interface for monitoring operations and configuring linkage alarm lights.

1. In the industry, Single Head Aseptic Bag Filling Machine backflows when filling products during whole process. But the Double Head Aseptic Bag Filling Machine and Multi head aseptic bag filling machines could continuously fill, reducing backflow and improving production efficiency, avoid backflow and re-sterilization resulting in loss of product color and flavor;

2. Adopts high quality 304 stainless steel material, contact part with product is SUS316L(Optional);

3. Easy to use German Siemens control system, equipped with Germany Siemens PLC and Germany Siemens touch screen;

4. Quick and easy CIP cleaning and SIP sterilization;

5. provide a variety of safety measures (position control, measurement control, temperature control, self-diagnosis and alarm) to prevent mechanical damage;

6. Mirror welding technology is adopted to ensure smooth welding seam and reduce product residue;

7. CIP and SIP are performed simultaneously with the sterilizer;

8. Adopt Italian technology can easily ensure the sterility of the entire filling process;

9. All flanges in the machine are specially designed with steam protection to ensure that the products in the pipeline remain sterile;

10. Flexible manufacturing that is highly adaptable to changing needs, whether bag size, accessories or packaging design;

11. Ensure production safety and commercial sterility by adhering to sterility verification protocols;

12. Quickly and accurately fill liquid foods and high-viscosity liquid foods.

Aseptic Filling Machine uses steam injection to sterilize the bag mouth and keep the filling room always in a sterile state. The sterilization, opening, filling and sealing of the aseptic bag mouth are all completed in a commercial sterile environment.

Manually insert the aseptic bag neck into the filling head to fill bags from 1-1,000 liters. Then an automatic cycle of opening, filling and closing begins. During this cycle, the temperatures of the steam injectors and filling valves are carefully monitored and controlled.

For 1,000 liter bags, the product enters the bag with the filling head in the down position. This solution evenly distributes products, especially sticky products, within the bag and helps prevent corner folding.

Shanghai EasyReal Machinery Co., Ltd was established in 2011, which specializes in manufacturing fruit and vegetable production lines and key equipment of various aseptic filling machines like Single Head Aseptic Bag Filling Machine, Double Head Aseptic Bag Filling Machine and Multi head aseptic bag filling machines and so on. We are committed to providing users with a full range of services from R&D to production. Now we have obtained CE certification, ISO9001 quality certification, and SGS certification, and have 40+ independent intellectual property rights in the fruit and vegetable processing field.

Our engineering team has nearly 20+ years of experience. Currently, we have served more than 300+ projects, such as tomato paste production line, mango juice/pulp production line, mango concentrated pulp production line, carrot processing line, coconut processing line and multi-fruit fruit and vegetable processing. Line. EasyReal Company sincerely welcomes you to visit our company and our customers' factories for field inspection.

1. Fruit Concentrate Aseptic Filling

2. Fruit Juice Aseptic Filling

3. Fruit Pulp Aseptic Filling

4. Fruit Puree Aseptic Filling

5. Concentrate Fruit Juice Aseptic Filling

6. Concentrate Fruit Pulp Aseptic Filling

7. Concentrate Fruit Puree Aseptic Filling

8. Tomato paste 36-38brix & 28-30brix & so on.