Aseptic Bag Filling Machine for BIB/BID/BIC (1–1500L)

The EasyReal aseptic bag filling machine family supports three mainstream formats (BIB, BID, and BIC/IBC liners). Select the best option by your packaging size and supply-chain plan.

Bag-in-Box (BIB) aseptic filling equipment (1–25L)

BIB is widely used for flexible small packs, sampling/export distribution, and downstream co-packing

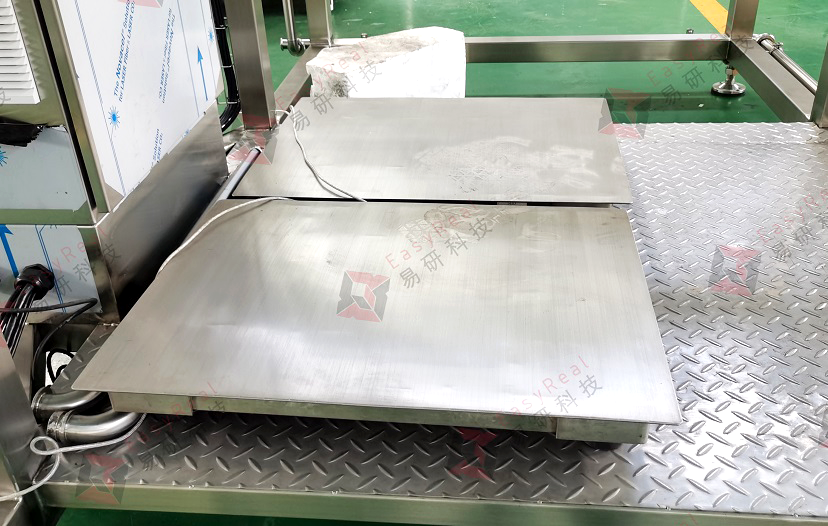

Bag-in-Drum (BID) aseptic bag in drum filling system (200-250L)

BID is the classic export format for tomato paste, fruit/vegetable concentrates, and semi-finished liquids shipped to factories for blending, reprocessing, or retail packing.

Bulk BIC / IBC liner aseptic filling (1000-1500L)

Bulk liners are designed for high-volume industrial supply chains and warehouse-efficient transport where large-capacity aseptic storage reduces packaging labor and improves logistics cost structure.

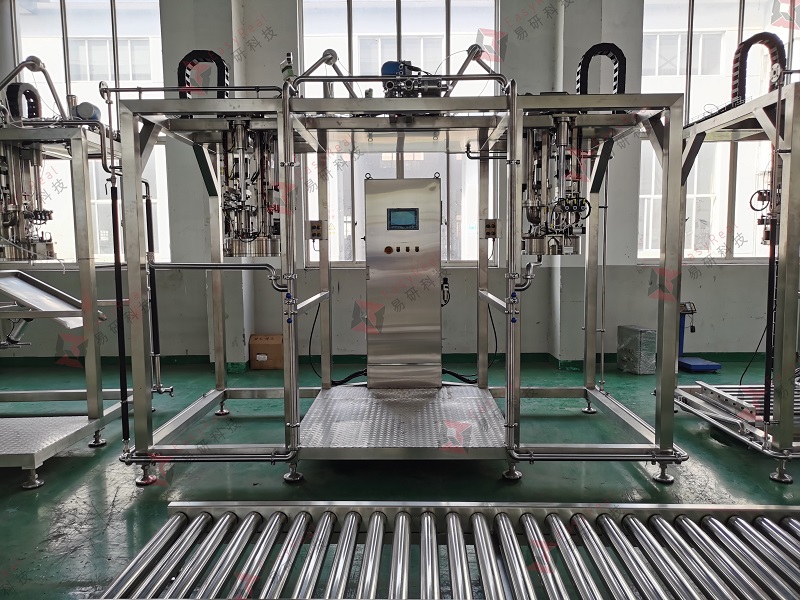

In aseptic bag packaging, the “real core” is the aseptic filling head and the repeatability of the sterilization-and-fill cycle. This machine integrates:

•Steam sterilization unit for the filling interface

•A protected filling zone designed to reduce contamination risk during operation

•SIP/CIP integration as part of hygienic line operation and changeovers

Typical aseptic filling cycle

1.Select bag type and parameters on the HMI

2.Steam sterilize the spout/interface zone

3.Fill with metering control (flow meter or weighing)

4.Seal/close in a controlled environment

5.Convey out for storage or shipping

1.Robust Construction

Premium SUS304 stainless steel main structure ensures corrosion resistance and compliance with food-grade hygiene standards.

2.European Engineering Excellence

Combines Italian processing technology with German automation systems, fully compliant with Euro Standard EN 1672-2.

3.Multi-Scale Compatibility

Spout sizes: 1"/2" (25mm/50mm) standard options

Bag capacity: 200L-220L standard models (Customizable from 1L to 1500L)

4.Smart Control System

Independent Siemens S7-1200 PLC with HMI touchscreen enables precise parameter control and real-time monitoring.

5.Sterilization Assurance

Full SIP/CIP integration (pH-resistant surfaces)

Steam barrier protection for filler head (120°C sustained)

Triple-sealed moving components

6.Dual Precision Measurement

Option for:

✓ Coriolis mass flowmeter (±0.3% accuracy)

✓ Dynamic weighing system (±5g resolution)

7.Maintenance-Optimized Design

Tool-free quick-change parts

<30 min CIP cycle time

Universal connector interfaces

8.Global Component Strategy

Critical systems feature:

• Festo/Burkert pneumatics

• SICK sensors

• Nord gearmotors

• IFM monitoring modules

9.Energy Efficiency

≤0.15kW·h/L power consumption with heat recovery system

10.Certification Ready

Pre-configured for CE/PED/3-A certification documentation

AF2 (BIB 1–25L) — dedicated bag-in-box aseptic filler

- AF2S: BIB single head, capacity up to 3 t/h, power 1 kW

- AF2D: BIB double head, capacity up to 5 t/h, power 2 kW

- Metering: Flow meter

AF1 (BID 200-250L) — aseptic bag in drum filling system

- AF1S: BID single head, capacity up to 6 t/h, power 1 kW

- AF1D: BID double head, capacity up to 12 t/h, power 2 kW

- Metering: Weighing system or flow meter

AF3 (BIB + BID 1–250L) — wide-range multi-format machine

- AF3S / AF3D: supports BIB & BID, bag size 1–250 L, capacity up to 12 t/h, power 1 kW / 2 kW (single/double)

- Metering: Weighing system or flow meter

AF4 (BID + BIC 200-1500/200/220/1000/1500L) — bulk export configuration

- AF4S / AF4D: supports BID & BIC, bag size 200/220/1000/1500 L, capacity up to 12 t/h, power 4.5 kW / 9 kW (single/double)

- Metering: Weighing system or flow meter

Utilities (common reference)

- Steam: 0.6–0.8 MPa, approx 50 kg/h (single head) / 100 kg/h (double head)

- Air: 0.6–0.8 MPa, approx 0.04 m³/h (single head) / 0.06 m³/h (double head)

If you prefer selection by “bags/hour” instead of t/h, share product type + viscosity + target bag size, and we’ll convert capacity into a realistic cycle-time estimate.

|

Name |

Single head Aseptic Bag in Drum Filling System |

Double head Aseptic Bag in Drum Filling System |

Bag in box Single head Aseptic Filler |

Bag in box Double head Aseptic Filler |

BIB & BID Single head Aseptic bag Filling Machine |

BIB & BID Double head aseptic bag Filling Machine |

BID & BIC Single head Aseptic liquid Filling Machine |

BID & BIC Double head Aseptic liquid Filling Machine |

|

Model |

AF1S |

AF1D |

AF2S |

AF2D |

AF3S |

AF3D |

AF4S |

AF4D |

|

Bag Type |

BID |

BIB |

BIB & BID |

BID & BIC |

||||

|

Capacity |

up to 6 |

up to 12 |

up to 3 |

up to 5 |

up to 12 |

up to 12 |

up to 12 |

up to 12 |

|

Power |

1 |

2 |

1 |

2 |

4.5 |

9 |

4.5 |

9 |

|

Steam Consumption |

0.6-0.8 Mpa≈50(Single head)/≈100(Double head) |

|||||||

|

Air Consumption |

0.6-0.8 Mpa≈0.04(Single head)/≈0.06(Double head) |

|||||||

|

Bag Size |

200, 220 |

1 to 25 |

1 to 220 |

200, 220, 1000, 1500 |

||||

|

Bag Mouth Size |

1" & 2" |

|||||||

|

Metering Method |

Weighing System or Flow Meter |

Flow Meter |

Weighing System or Flow Meter |

|||||

|

Dimension |

1700*2000*2800 |

3300*2200*2800 |

1700*1200*2800 |

1700*1700*2800 |

1700*2000*2800 |

3300*2200*2800 |

2500*2700*3500 |

4400*2700*3500 |

Different products behave differently (viscosity changes, foaming, density variation). EasyReal supports two mainstream methods plus an accuracy-focused option:

Flow meter filling (suitable for 1-1500L, more accurate)

When you have high requirements for filling accuracy and frequently need to fill small bags and many juice/puree products.

Weighing filling (Typically used for BID & BIC )

Best when viscosity changes (paste, sauce, concentrated puree) and you want robust net-content control.

• Main structure: SUS304/316L stainless steel for hygienic, corrosion-resistant service

• Control: Independent Siemens S7-1200 PLC + HMI touchscreen for parameter setting and monitoring

• Bag/spout compatibility: 1" / 2" standard spout sizes

• Published design notes include EN 1672-2 compliance positioning and sterilization/ sealing protections

This aseptic bag filling machine is commonly used for semi-finished products destined for factories or export, including:

• Tomato paste & vegetable concentrates

• Fruit pulps and purees (mango, guava, peach, etc.)

• NFC juice and concentrates

• Jams, syrups, sauces, soups/broths, liquid seasonings

• Coconut water and derivatives (milk/cream) where aseptic packaging helps stabilize distribution

Process inputs we need for correct configuration (fast selection):

pH range, Brix/solids, viscosity range, particle size (if any), target bag size, and target throughput.

Bag sizes by model

• AF1 (BID): 200, 220 L

• AF2 (BIB): 1–25 L

• AF3 (BIB & BID): 1–220 L

• AF4 (BID & BIC): 200, 220, 1000, 1500 L

Dimensions (mm)

• AF1S: 1700×2000×2800 | AF1D: 3300×2200×2800

• AF2S: 1700×1200×2800 | AF2D: 1700×1700×2800

• AF3S: 1700×2000×2800 | AF3D: 3300×2200×2800

• AF4S: 2500×2700×3500 | AF4D: 4400×2700×3500

We support your project from selection to commissioning and operation continuity:

• Food-contact surface and sealing material compliance positioning (SUS304 + FDA/EC references listed on this page)

• Engineering deliverables and documentation workflow (drawings, FAT-style documentation package availability)

• Training and service commitments listed on this page (warranty, remote support targets, lifecycle support)

The EasyReal aseptic bag filling machine family supports three mainstream formats (BIB, BID, and BIC/IBC liners). Select the best option by your packaging size and supply-chain plan.

Q1: How is sterility maintained during filling?

This aseptic filling machine employs multiple measures, including three-point steam jet sterilization and steam barrier protection, to achieve a commercially sterile environment. and can be integrated into SIP/CIP routines for repeatable hygiene control.

Q2: Which metering should I choose—flow meter or weighing?

Flow meters are generally suitable for filling various bag types and offer high accuracy, while weighing systems are primarily used for BID and BIC packaging.

Q3: Can it fill viscous products like tomato paste or jam?

Yes—this page positions suitability for viscous products; for the final configuration we confirm viscosity/Brix/particle size and recommend the best metering and valve path accordingly.

Q4: What bag mouth size does it support?

Standard options are 1" and 2" (25mm/50mm)

Q5: Single head vs double head—how do I decide?

Choose double head when you need higher throughput and stable continuous operation; choose single head when product throughput demand is moderate.

Q6: Is this machine for pouches?

This page is for aseptic bags (BIB/BID/BIC). If you need pouch filling, share your pouch type and we’ll confirm the correct solution.

Q7: Can it integrate with UHT/HTST and an aseptic tank?

Yes—this page positions integration with UHT sterilizers to form a complete aseptic line; we can provide layout and module matching based on your factory utilities and throughput.

EasyReal Tech. is a leading manufacturer of fruit and vegetable processing line equipment, offering tailored turnkey solutions from A to Z, designed to meet each client's specific needs. Among our core products, the Aseptic Bag-in-Drum Filling System stands out as the most popular. This machine has earned multiple patents and is widely praised by customers for its safety and reliability.

To date, EasyReal has achieved ISO9001 quality certification, European CE certification, and the prestigious State-certified High-tech Enterprise honor. Through long-term collaborations with internationally renowned brands such as Germany's STEPHAN, Germany's RONO, and Italy's GEA, we have developed over 40 pieces of equipment with independent intellectual property rights. Our products have been trusted by major corporations including Yili Group, Ting Hsin Group, Uni-President Enterprise, New Hope Group, Pepsi, Myday Dairy, and more.

As EasyReal continues to evolve, we now offer comprehensive one-stop services that cover everything from project consultation and process development to solution design, construction, and after-sales support. We provide customized services tailored to the unique needs of each client, striving to deliver projects that exceed expectations.