Coconut Processing Line

Mzere wamafakitalewu umapereka mkaka wochuluka wa kokonati ndi kupanga madzi kwa opanga zakumwa ndi zopangira.

Oyendetsa amadyetsa coconut opanda mankhusu m'dongosolo, zomwe zimadula, kukhetsa, ndikulekanitsa madzi ndi zamkati.

Gawo la mkaka limagaya ndi kukanikiza kernel ndikutenthetsa bwino kuti mutulutse zonona za kokonati.

Masensa otsekedwa-loop amawunika kuthamanga, kutentha pagawo lililonse.

Dongosolo lapakati la PLC limayang'anira magawo otentha, kuziziritsa, ndi kutsekereza.

Ma HMI a touchscreen amalola ogwiritsa ntchito kuyika kutentha, kukakamiza, kuyang'ana zomwe zikuchitika, ndikutsata zolemba zomwe amapanga.

Mayendedwe a CIP odzichitira okha amatsuka polumikizana ndi zitsulo zosapanga dzimbiri pakatha kusintha kulikonse popanda kuthyola mapaipi kapena akasinja.

Mapaipi onse amagwiritsa ntchito sanitary 304/316 chitsulo chosapanga dzimbiri, ma gaskets a chakudya, ndi zotchingira mwachangu pokonza bwino.

Masanjidwe amatsatira modular logic.

Gawo lirilonse-kukonzekera, kuchotsa, kusefera, kukhazikika, kutseketsa, ndi kudzaza-kumayenda ngati gawo lodziyimira pawokha.

Mutha kukulitsa zotulutsa kapena kuwonjezera ma SKU atsopano osayimitsa mzere waukulu.

Zotsatira zake, mafakitole amapeza zinthu zokhazikika komanso nthawi yochepa.

Mafakitale opangira mkaka wa kokonati amagwira ntchito m'magawo angapo:

• Mafakitole a zakumwa omwe amabotolo madzi a kokonati kapena zakumwa zoziziritsa kukhosi.

• Okonza zakudya akupanga kokonati kirimu wa ayisikilimu, ophika buledi, ndi ma dessert.

• Mayunitsi otumiza kunja omwe akulongedza mkaka wa UHT ndi madzi kumisika yapadziko lonse komanso misika ya HORECA.

• Opereka zosakaniza omwe amapereka mkaka wosiyana ndi zakudya zamasamba.

Fakitale iliyonse imayang'anizana ndi zowunikira zaukhondo, kulondola kwa zilembo, komanso moyo wa alumali.

Mzerewu umasunga mbiri ya kutentha ndi batch data, kukuthandizani kuti mudutse macheke a ISO ndi CE mosavuta.

Mavavu odzipangira okha ndi maphikidwe anzeru amachepetsa zolakwika za ogwiritsa ntchito, zomwe zikutanthauza kuti madandaulo amakasitomala amachepera komanso kutumizira mwachangu.

Mkaka wa kokonati ndi madzi zimakhala ndi zoopsa zapadera.

Amanyamula ma enzyme ndi mafuta achilengedwe omwe amawonongeka mwachangu akatenthedwa mosagwirizana.

Viscosity imasintha mofulumira ndi kutentha, choncho, ngati kukonza kuli kwautali, zipangizo ziyenera kuziziritsidwa mwamsanga ndi kusungidwa pa kutentha kochepa kuti zisawonongeke chifukwa cha kukonza kwautali.

Mzerewu wopanga mafakitale umagwiritsa ntchito homogenizer kuonetsetsa kugawa mafuta a mkaka wa kokonati.

Adopt Vacuum de-aeration imachotsa thovu la mpweya lomwe limayambitsa makutidwe ndi okosijeni komanso kutaya kukoma.

Adopt Tubular UHT Sterilizer kuti muwonetsetse kuti zinthu zisamasamalidwe bwino

Tanki iliyonse imakhala ndi mipira yopopera ya CIP kuti iphe majeremusi ndikuchotsa zotsalira zamafuta pambuyo popanga.

Zotsatira zake zimakhala zoyera komanso zosasinthasintha zomwe zimasunga mtundu woyera wa kokonati ndi fungo labwino.

Yambani ndi zomwe mukufuna kutulutsa.

Mwachitsanzo, kusintha kwa maola 8 pa 6,000 L/h kumapereka ≈ matani 48 a mkaka wa kokonati patsiku.

Sankhani kuchuluka kwa zida kuti zigwirizane ndi kukula kwa msika wanu ndi kusakaniza kwa SKU.

Zofunikira zazikulu ndi izi:

• Malo otenthetsera kutentha ndi kuchuluka kwa vacuum mu sterilizer.

• Mtundu wa agitator (mtundu wa scraper wa mizere ya kirimu; wometa ubweya wambiri wa mkaka).

• Ma diameter a mapaipi ndi mavavu ochulukitsa omwe amathandizira CIP yokhazikika komanso kusintha mwachangu.

• Njira yodzaza (chikwama cha aseptic, botolo lagalasi, can, kapena PET).

Tikukulimbikitsani kuti mutsimikizire zoyeserera musanasanjidwe komaliza kuti mutsimikizire kuchuluka kwa kutentha ndi kuchuluka kwake.

Mainjiniya athu ndiye amakulitsa dongosololi kuti lifike pamapangidwe anu amakampani komanso dongosolo lothandizira.

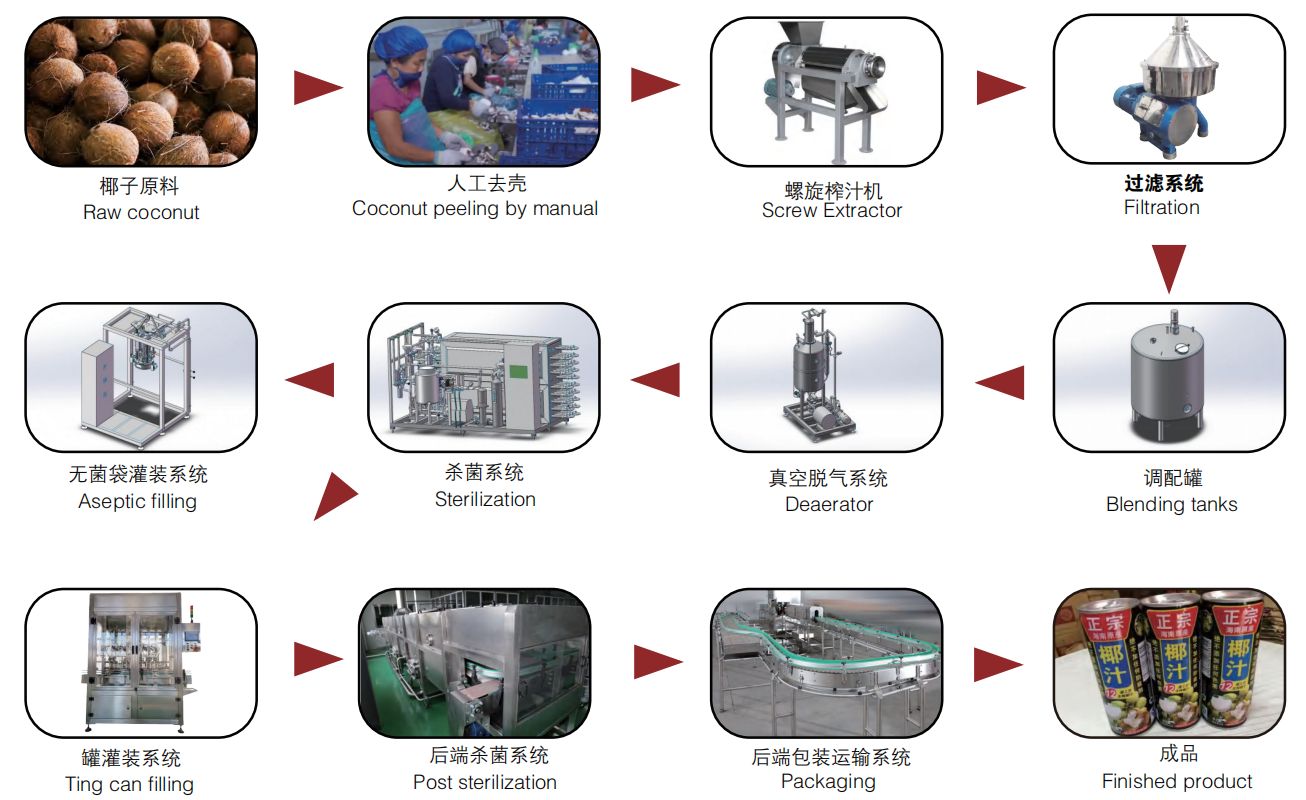

1. Kudya Kwaiwisi ndi Kusanja

Ogwira ntchito amanyamula coconuts opanda mankhusu pa lamba wodyera.

2. Kusweka ndi Kusonkhanitsa Madzi

Makina obowola amatsegula mabowo a kokonati kuti atulutse madzi ndikuwatengera mu thanki yosungiramo kuti apewe fumbi.

3. Peeling Kernel ndi Kuchapa

Nyama ya kokonatiyo amasenda, kutsukidwa, ndikuyang’aniridwa ngati ali ndi madontho abulauni kuti asunge mtundu wake woyera.

4. Kupera ndi Kukanikiza

Mphero zothamanga kwambiri zimaphwanya zamkati kukhala tizigawo ting'onoting'ono, ndipo makina osindikizira amatulutsa mkaka wa kokonati.

5. Sefa ndi Standardization

Zosefera zimachotsa ulusi ndi zolimba. Othandizira amasintha mafuta molingana ndi zomwe amapangira.

6. Homogenization ndi De-aeration

Mkaka umadutsa mu homogenizer yothamanga kwambiri ndi vacuum deaerator kuti ukhazikike ndikuchotsa mpweya. mayunitsi akhoza chikugwirizana pakati ndi chowumitsa choziziritsa kukhosi mosalekeza homogenization ndi degassing.

7. Kutseketsa

Ma sterilizer amatenthetsa mkaka mpaka 142 ° C kwa masekondi 2-4 (UHT). Machubu-mu-chubu amanyamula mizere yamafuta ochuluka komanso owoneka bwino kwambiri.

8. Kudzaza

Chogulitsacho chimazizira mpaka 25-30 ° C ndipo chimadzazidwa ndi aseptic filler.

9. CIP ndi Changeover

Pambuyo pa gulu lililonse, makinawa amayendetsa kuzungulira kwa CIP kokhazikika kokhala ndi ma rinses amchere ndi asidi kuti akhale aukhondo komanso kuchepetsa nthawi yopuma.

10. Kuyendera komaliza ndi kulongedza katundu

Inline mamasukidwe akayendedwe ndi Brix mamita amatsimikizira kusasinthasintha pamaso katoni ndi palletizing.

Njira yofananayi imagwiranso ntchito pamizere yopangira madzi a kokonati, ndikusinthidwa pang'ono pagulu la fyuluta ndi kutentha kotsekereza kuti musunge ma electrolyte achilengedwe.

1. Kokonati Pobowola Machine ndi Madzi Osonkhanitsa

Makina obowola amabowola kabowo kakang'ono mu kokonati, kusunga madzi ndi kernel zonse momwe zingathere.

Njira yachitsulo yosapanga dzimbiri imasonkhanitsa madzi a kokonati pansi pa chivindikiro chotsekedwa kuti ateteze majeremusi kapena fumbi.

Sitepe amateteza zachilengedwe kukoma pamaso waukulu m'zigawo.

2. Gawo la Mkaka Wa Kokonati

Gawoli limaphatikiza chopukusira ndi chosindikizira chamadzimadzi.

Imaphwanya nyama ya kokonati m'tinthu ting'onoting'ono ndipo imagwiritsa ntchito makina osindikizira kufinya mkaka wa kokonati.

Poyerekeza ndi makina osindikizira amanja, imapangitsa kuti mafuta azitulutsa ndi 30% ndikupangitsa kuti mafuta azikhala osasinthasintha.

3. Sefa ndi Centrifuge System kwa Kokonati Madzi

Sefa yama mesh ya magawo awiri imachotsa ulusi waukulu m'madzi a kokonati.

Kenako, disc centrifuge imalekanitsa tizigawo ta madzi, mafuta opepuka, ndi zonyansa.

Kulekanitsa uku kumapangitsa kumveka bwino kwa mankhwala a kokonati.

4. Homogenizer

Makina opangira mkaka wa kokonati akuphatikizapo homogenizer yapamwamba kwambiri kuti akhazikitse emulsion.

Pakukakamiza kwa 40 MPa, imaphwanya ma globules amafuta kukhala tinthu tating'onoting'ono.

Mkaka umakhala wosalala ndipo sumalekanitsa panthawi yosungidwa.

Gawo ili ndilofunika kwambiri kuti pakhale bata muzakumwa za kokonati.

5. UHT Sterilizer

Kusankha chubu chowumitsa machubu kapena chubu-in-chubu sterilizer zimatengera fluidity ya mankhwala.

Madzi a kokonati amafunika kutentha pang'ono kuti asunge fungo; kokonati kirimu imafuna kutenthedwa msanga kuti isapse.

Kuwongolera kwa PLC kumasunga kutentha mkati mwa ± 1 °C wa malo okhazikika.

Mapangidwe obwezeretsa mphamvu a tubular sterilizer amathandiza makasitomala kuchepetsa ndalama zogwirira ntchito.

6. Makina Odzaza Aseptic

Makina opangira madzi a kokonati amamaliza ndi njira yosabala yodzaza.

Njira zonse zopangira zida zimapangidwa ndi SUS304 kapena SUS316L chitsulo chosapanga dzimbiri.

Itha kugwira ntchito ndi chowumitsa pamodzi kuti izindikire CIP yapakati ndi SIP.

Izi zimatsimikizira moyo wautali wa alumali popanda zotetezera.

7. CIP Kuyeretsa System

CIP skid yodzichitira yokha imasakaniza madzi, alkali, ndi asidi kuyeretsa akasinja ndi mapaipi.

Imayenda mozungulira mosiyanasiyana ndikuyenda, nthawi, komanso kutentha.

Othandizira amasankha maphikidwe pa HMI ndikuwona kupita patsogolo kwanthawi yeniyeni.

Izi zimadula nthawi yoyeretsa ndi 40% ndikusunga makina onse opangira kokonati kukonzekera gulu lotsatira.

Mafakitole amatha kuyendetsa magwero osiyanasiyana a kokonati popanda kusintha mzere waukulu.

Ma coconut atsopano, owumitsidwa, kapena okonzedwa pang'ono onse amakwanira gawo lokonzekera lomwe.

Zomverera zimasintha liwiro ndi kutentha kuti zigwirizane ndi zolimba zamtundu uliwonse ndi mafuta.

Mukhozanso kuyendetsa mitundu ingapo yotulutsa:

• Madzi a kokonati oyera mu PET, galasi, kapena tetra-pack.

• Mkaka wa kokonati ndi zonona zophikira kapena zokometsera.

• Coconut maziko okhazikika kuti akhazikitsenso misika yogulitsa kunja.

• Zakumwa zosakaniza ndi madzi a zipatso kapena mapuloteni a zomera.

Zosintha mwachangu komanso mavavu odzipangira okha amachepetsa nthawi yopumira pakusintha kwa SKU.

Kusinthasintha kumeneku kumathandiza zomera kukwaniritsa zofuna za nyengo ndi kupititsa patsogolo ntchito zopanga.

Dongosolo la PLC ndi HMI limapanga ubongo wa mzere wonse.

Ogwiritsa ntchito amatha kuyika maphikidwe omwe amafotokozedwatu amkaka kapena zinthu zamadzi ndikuwunika tanki iliyonse ndi kupopera munthawi yeniyeni.

Zida zanzeru zikuphatikiza:

• Chophimba chapakati chapakati chokhala ndi ma graph amakono ndi deta ya batch.

• Kupeza mwayi kwa ogwira ntchito, oyang'anira, ndi ogwira ntchito yosamalira.

• Ulalo wa Ethernet wowunikira kutali ndi chithandizo chautumiki.

• Kutsata kagwiritsidwe ntchito ka mphamvu ndi madzi pagulu lililonse.

Zolumikizira zokha zimalepheretsa kuti zinthu zisamayende bwino, zomwe zimateteza zida ndi zida.

Mzerewu umakhala wokhazikika pamasinthidwe onse, ngakhale ndi maphunziro ochepa oyendetsa.

EasyReal imathandizira pulojekiti yanu kuyambira pamalingaliro mpaka pakutumiza.

Gulu lathu limaphunzira mawonekedwe anu azinthu, kuyika, ndi mawonekedwe ogwiritsira ntchito kuti apange njira yoyenera.

Timatumiza:

• masanjidwe ndi kapangidwe ka P&ID.

• Kupereka zida, kuyika, ndi kutumiza pamalopo.

• Maphunziro a oyendetsa, zida zosinthira, ndi ntchito zakutali m'nyengo yanu yoyamba yopanga.

Chomera chilichonse chopangira mkaka wa kokonati chimatsatira miyezo yapadziko lonse yaukhondo ndi chitetezo, yokhala ndi ziphaso za CE ndi ISO.

Mafakitole ku Asia, Africa, ndi Latin America amayendetsa kale mizere ya EasyReal yopanga malita masauzande pa ola la mkaka wa kokonati ndi madzi tsiku lililonse.

Lumikizanani nafe kuti tikambirane za kuchuluka kwa zomwe mukufuna komanso kalembedwe kanu.

Tikuthandizani kukonza makina oyenera a kokonati kuti muwonjeze ntchito yanu bwino.