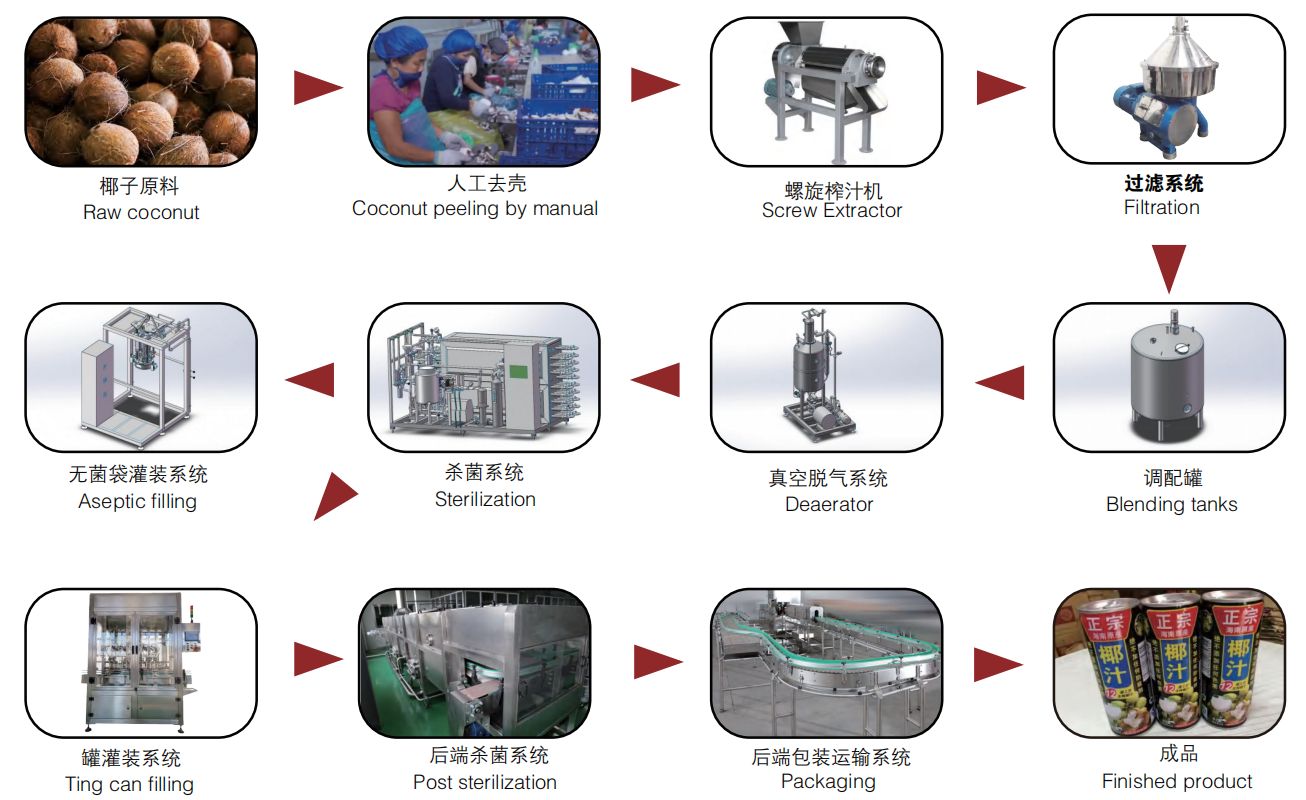

Coconut Processing Line

Iyi mutsara weindasitiri unoburitsa yakakwira-vhoriyamu mukaka wekokonati uye kugadzirwa kwemvura kune zvinwiwa uye zvinosanganisa vanogadzira.

Vashandi vanodyisa de-husked coconuts muhurongwa, iyo inocheka, inobvisa, uye inoparadzanisa mvura uye pulp.

Chikamu chemukaka chinogaya uye chinodzvanya kernel pasi pekudziya kwakadzora kuburitsa coconut cream.

Yakavharwa-loop sensors inotarisisa kudzvanywa, tembiricha mumatanho ese.

Iyo yepakati PLC sisitimu inogadzirisa kudziyisa, kutonhora, uye sterilization zvikamu.

Bata-screen HMIs rega vashandisi kuseta tembiricha, kudzvanywa, tarisa mafambiro, uye kuteedzera marekodhi ekugadzira.

Automated CIP cycles inochenesa nzvimbo isina simbi-yekusangana mushure mekuchinja kwega kwega pasina kubvisa pombi kana matangi.

Mapaipi ese anoshandisa hutsanana 304/316 simbi isina tsvina, chikafu-giredhi gaskets, uye inokurumidza-clamp fittings kuchengetedza zvakachengeteka.

Mamiriro acho anotevera modular logic.

Chikamu chega chega-kugadzirira, kudhirowa, kusefa, kuenzanisa, sterilization, uye kuzadza-inomhanya sechikamu chakazvimirira.

Unogona kuwedzera kuburitsa kana kuwedzera maSKU matsva pasina kumisa mutsara mukuru.

Nekuda kweizvozvo, mafekitori anowana yakatsiga chigadzirwa mhando nekushomeka kuderera.

Indasitiri kokonati mukaka wekugadzira zvidyarwa zvinoshandira akati wandei zvikamu:

• Mafekitari ezvinwiwa anobhotorosa mvura yekokonati yakachena kana zvinwiwa zvinonaka.

• Magadzirirwo echikafu anogadzira coconut cream yeaizikirimu, bhekari, uye mabhesi ekudya.

• Export units inorongedza mukaka nemvura yeUHT yemisika yepasi rose yekutengesa neyehoreCA.

• Vagadziri vezvekudya vanopa mishonga yemukaka uye magadzirirwo emhuka.

Imwe neimwe fekitori inotarisana nekuongororwa kwakasimba pahutsanana, kurongeka kwemavara, uye hupenyu hwesherufu.

Mutsetse uyu unochengeta marekodhi ekushisa uye batch data, zvichikubatsira kuti upfuure ISO uye CE kutevedza macheki zviri nyore.

Iwo otomatiki mavharuvhu uye akangwara ekubika anodzikisa kukanganisa kwevashandisi, zvinoreva kushoma kunyunyuta kwevatengi uye kuendesa kwakadzikama.

Kokonati mukaka nemvura zvine njodzi dzakasiyana.

Vanotakura ma enzymes echisikigo nemafuta anoshatisa nekukurumidza kana apiswa zvisina kuenzana.

Viscosity inoshanduka nekukurumidza nekushisa, saka, kana kugadzirisa kwakareba, zvinhu zvakasvibirira zvinoda kutonhodzwa nekukurumidza uye kuchengetwa pakudziya kwakaderera kudzivirira rancidity inokonzerwa nekureba kugadzirisa.

Iyi tambo yekugadzira maindasitiri inoshandisa homogenizer kuve nechokwadi chekugovaniswa kwemafuta emukaka wekokonati.

Adopt Vacuum de-aeration inobvisa mabhuru emhepo anokonzeresa oxidation uye kurasika kurasika.

Adopt Tubular UHT Sterilizer kuve nechokwadi chekuita sterilization yezvigadzirwa

Tangi yega yega ine CIP yekupfapfaidza mabhora ekuuraya utachiona uye kubvisa mafuta akasara mushure mekugadzirwa.

Mhedzisiro ndeyekubuda kwakachena, kunoenderana kunochengeta coconut ruvara ruchena uye kunhuhwirira kutsva.

Tanga nezvawakananga kuburitsa.

Semuenzaniso, 8-awa yekuchinja pa6,000 L / h inopa ≈48 matani emukaka wekokonati pazuva.

Sarudza huwandu hwemidziyo inoenderana nehukuru hwemusika wako uye SKU musanganiswa.

Zvikamu zvakakosha zvinosanganisira:

• Kupisa-kuchinjisa nzvimbo uye vacuum range mu sterilizer.

• Rudzi rwe agitator (scraper type for cream lines; high-shear yemukaka).

• Madhayamita epombi uye mavharuvhu akawanda anotsigira otomatiki CIP uye nekukurumidza kuchinja.

• Kuzadza nzira (aseptic bag, glass bottle, can, kana PET).

Isu tinokurudzira kuongororwa kwemutyairi pamberi pekupedzisira dhizaini kuratidza kupisa mwero uye goho.

Mainjiniya edu anobva ayera sisitimu kusvika kune yako maindasitiri tsoka uye chirongwa chekushandisa.

1. Raw Intake uye Kuronga

Vashandi vanoisa makokonati akabviswa husked pabhandi rekudyisa.

2. Kupwanya uye Kuunganidza Mvura

Muchina wekuchera unovhura makomba mukokonati kuburitsa mvura uye kuiunganidza mutangi yekuchengetedza kudzivirira guruva.

3. Kernel Peeling uye Washing

Nyama yekokonati inopepetwa, yogezwa, uye yoongororwa makwapa ebrown kuti irambe iine ruvara ruchena.

4. Kukuya nekudzvanya

Zvigayo zvinomhanya-mhanya zvinopwanya pulp kuita zvidimbu zvidiki, uye muchina wemuchina unobvisa hwaro hwemukaka wekokonati.

5. Filtration uye Standardization

Mafirita anobvisa mafiibhi nezvakaoma. Vashandi vanogadzirisa mafuta emukati maererano nezvinodiwa zvechigadzirwa.

6. Homogenization uye De-aeration

Mukaka unopfuura nemu-high-pressure homogenizer uye vacuum deaerator kuti ugadzikane maitiro uye kubvisa mweya. Aya mayunitsi anogona kubatanidzwa inline ne sterilizer yekuenderera mberi homogenization uye degassing.

7. Kuvharisa

Tubular sterilizers inopisa mukaka kusvika 142 °C kwemasekonzi maviri-4 (UHT). Tube-in-tube sterilizers inobata yakakwira-mafuta uye yakakwirira-viscosity cream mitsetse.

8. Kuzadza

Chigadzirwa chinotonhora kusvika 25-30 ° C uye chinozadzwa uchishandisa aseptic filler.

9. CIP uye Changeover

Mushure mebatch yega yega, sisitimu inomhanyisa yakazara otomatiki CIP kutenderera ine alkaline uye asidhi rinses kuchengetedza hutsanana uye kuderedza kuderera.

10. Kuongorora Kwekupedzisira uye Kurongedza

Inline viscosity uye Brix metres inosimbisa kuenderana kusati kwaita cartoning uye palletizing.

Iyo yakafanana musimboti maitiro anoshanda kune mitsetse yekugadzira mvura yekokonati, ine zvishoma zvigadziriso mugiredhi resefa uye tembiricha yekudzivirira kuchengetedza ma electrolyte chaiwo.

1. Coconut Drilling Machine uye Water Collector

Muchina wekuchera unongoboora buri diki mukokonati, uchichengeta zvese mvura nekernel zvisina kusimba zvakanyanya sezvinobvira.

Mugero wesimbi isina tsvina unounganidza mvura yekokonati pasi pechivharo chakavharwa kudzivirira utachiona kana huruva.

Iyi nhanho inodzivirira kunhuhwirira kwechisikigo kusati kwanyanya kutorwa.

2. Coconut Milk Extraction Chikamu

Ichi chikamu chinobatanidza grinder uye juice screw presser.

Inotyora nyama yekokonati kuita zvidimbu zvidiki uye inoshandisa screw presser kusvina mukaka wekokonati.

Kana ichienzaniswa nemichina yekutsikisa, inovandudza kubuda nepamusoro pe30% uye inochengeta mazinga emafuta anoenderana.

3. Filtration uye Centrifuge System yeCoconut Water

Sefa ine-matanho maviri mesh inobvisa mafibhi makuru mumvura yekokonati.

Zvadaro, disc centrifuge inoparadzanisa zvikamu zvemvura, mafuta akareruka, uye tsvina.

Kupatsanurwa uku kunonatsiridza coconut mvura chigadzirwa kujeka.

4. Homogenizer

Iko coconut mukaka wekugadzira muchina unosanganisira yakakwira-kumanikidza homogenizer kudzikamisa emulsion.

Pa40 MPa kudzvanywa, inopwanya mafuta globules kuita diki-saizi particles.

Mukaka unoramba wakatsetseka uye hauparadzanise panguva yekuchengetera.

Iyi nhanho ndiyo kiyi yekugadzikana kwesherufu muzvinwiwa zvekokonati.

5. UHT Sterilizer

Kusarudza tubular sterilizer kana chubhu-in-tube sterilizer zvinoenderana nekuyerera kwechigadzirwa.

Mvura yekokonati inoda kupisa zvishoma kuti irambe ichinhuhwirira; coconut cream inoda kupisa nekukurumidza kudzivirira kupisa.

PLC inodzora inochengeta tembiricha mukati me ± 1 °C yeiyo setpoint.

Iyo simba rekudzoreredza dhizaini ye tubular sterilizer inobatsira vatengi kuderedza mari yekushandisa.

6. Aseptic Kuzadza Machine

Muchina wekugadzirisa mvura wekokonati unopedzisa neine sterile yekuzadza system.

Nzira dzese dzechigadzirwa dzakagadzirwa neSUS304 kana SUS316L simbi isina tsvina.

Inogona kushanda neinouraya pamwechete kuti ione inline CIP uye SIP.

Izvi zvinovimbisa hupenyu hurefu hwesherufu pasina zvinodzivirira.

7. CIP Yekuchenesa System

Iyo otomatiki CIP skid inosanganisa mvura, alkali, uye asidhi kuchenesa matangi nemapombi.

Iyo inomhanya yakatsanangurwa matenderedzwa nekuyerera, nguva, uye tembiricha kutonga.

Vashandi vanosarudza mabikirwo paHMI uye vanoona kufambira mberi kwechokwadi-nguva.

Iyi nzira inocheka nguva yekuchenesa ne40% uye inochengeta muchina wese wekokonati wakagadzirira batch rinotevera.

Mafekitori anogona kumhanya akasiyana coconut masosi pasina kushandura main line.

Makonati matsva, akaomeswa nechando, kana semi-akagadziridzwa ese anokodzera chikamu chimwe chekugadzirira.

Masensa anogadzirisa kumhanya uye kudziyisa kuti ienderane nechinhu chimwe nechimwe chakasimba uye neoiri zvirimo.

Iwe unogona zvakare kumhanya akawanda anobuda marudzi:

• Mvura yekokonati yakachena muPET, girazi, kana tetra-pack.

• Mukaka wekokonati nekrimu yekubika kana dessert.

• Concentrated coconut base yekugadzirisa patsva mumisika yekunze.

• Zvinwiwa zvakasanganiswa nemuchero wemuchero kana mapuroteni emiti.

Kurumidza-kuchinja mafittings uye otomatiki mavharuvhu manifolds anoderedza kudzika panguva yeSKU shanduko.

Iko kuchinjika kunobatsira zvidyarwa kusangana nemwaka zvinodiwa uye kunatsiridza mashandisirwo ekugadzirwa.

Iyo PLC neHMI system inoumba huropi hwemutsara wese.

Vashandi vanogona kurodha zvakafanotsanangurwa zvekubika zvemukaka kana zvigadzirwa zvemvura uye kutarisa tangi yega yega uye pombi munguva chaiyo.

Smart maficha anosanganisira:

• Yepakati touchscreen ine maitiro magirafu uye batch data.

• Kuwanikwa kunoenderana nebasa revashandisi, vatariri, uye vashandi vekuchengetedza.

• Ethernet link yekutarisa kure nerutsigiro rwesevhisi.

• Simba uye kushandiswa kwemvura kutsvaga kwebatch yega yega.

Otomatiki interlocks inochengetedza zviito zvisina kuchengeteka kubva pakumhanya, izvo zvinodzivirira zvese chigadzirwa nemidziyo.

Mutsara unoramba wakatsiga pamashifiti ese, kunyangwe nekudzidziswa kwemufambisi kushoma.

EasyReal inotsigira purojekiti yako kubva pane pfungwa kusvika pakutumwa.

Chikwata chedu chinodzidza chigadzirwa chako fomula, kurongedza, uye utility dhizaini kugadzira yakaenzana maitiro.

Isu tinoendesa:

• marongerwo uye P&ID dhizaini.

• Equipment supply, installation, and commissioning on-site.

• Kudzidziswa kwevatyairi, zvikamu zvakasara, uye sevhisi iri kure yemwaka wako wekutanga wekugadzira.

Imwe neimwe coconut mukaka yekugadzira chirimwa inotevera hutsanana hwepasirese uye kuchengetedza zviyero, ine CE uye ISO zvitupa.

Mafekitari muAsia, Africa, uye Latin America anotomhanya EasyReal mitsetse inoburitsa zviuru zvemalita paawa yemukokonati mukaka nemvura zuva nezuva.

Bata isu kuti tikurukure yako yaunovavarira kugona uye maitiro ekurongedza.

Isu tichakubatsira iwe kugadzirisa iyo chaiyo coconut yekugadzirisa muchina kuti uwedzere kugadzirwa kwako nemazvo.