Coconut Processing Line

Lo mgca wezoshishino uhambisa ubisi lwekhokhonathi oluphezulu kunye nokuveliswa kwamanzi kutywala kunye nabavelisi bezithako.

Abaqhubi bondla iikhokhonathi ezisusiweyo kwisixokelelwano, esisika, sikhuphe, kwaye sahlule amanzi kunye nepulp.

Icandelo lobisi liyasila kwaye licinezele i-kernel phantsi kobushushu obulawulwayo ukukhulula i-coconut cream.

Izinzwa ezivaliweyo zijonga uxinzelelo, ubushushu kwinqanaba ngalinye.

Inkqubo esembindini ye-PLC ilawula izigaba zokufudumeza, ukupholisa, kunye nokuvala inzala.

Ii-HMI zesikrini esichukumisayo zivumela abaqhubi ukuba babeke ubushushu, uxinzelelo, ukujonga iintsingiselo, kunye nokulandelela iirekhodi zemveliso.

Imijikelo ye-CIP ezenzekelayo icoca iindawo zoqhagamshelwano zentsimbi engatyiwa emva kweshifti nganye ngaphandle kokuqhaqha imibhobho okanye iitanki.

Zonke iipayipi zisebenzisa i-sanitary 304/316 intsimbi engatyiwayo, iigaskets zebakala lokutya, kunye nokufakwa kwe-clamp ekhawulezayo ukuze kugcinwe ngokukhuselekileyo.

Uyilo lulandela ingqiqo yeemodyuli.

Icandelo ngalinye-ukulungiselela, ukutsalwa, ukuhluzwa, ukulinganisa, ukuvala inzala, kunye nokuzaliswa-isebenza njengeyunithi ezimeleyo.

Unokwandisa imveliso okanye ungeze ii-SKU ezintsha ngaphandle kokumisa umgca ongundoqo.

Ngenxa yoko, iifektri zifumana umgangatho wemveliso ozinzileyo kunye nexesha elincinci lokuphumla.

Imizi-mveliso yokuvelisa ubisi lwekhokhonathi ibonelela amacandelo amaninzi:

• Imizi-mveliso yeziselo evalela amanzi acocekileyo ekhokhonathi okanye iziselo ezinencasa.

• Abalungisi bokutya bavelisa i-coconut cream ye-ayisikrimu, indawo yokubhaka, kunye neziseko zezimuncumuncu.

• Iiyunithi ezithumela ngaphandle ezipakisha ubisi lwe-UHT namanzi kurhwebo lwehlabathi kunye neemarike zeHORECA.

• Ababoneleli bezithako banikezela ngeendlela ezizezinye zobisi kunye nemixube yezilwanyana.

Umzi-mveliso ngamnye ujongene nophicotho oluluqilima kucoceko, ukuchaneka kweelebhile, kunye nobomi beshelufu.

Lo mgca ugcina iirekhodi zobushushu kunye nedatha yebhetshi, kukunceda uphumelele i-ISO kunye ne-CE iitshekhi zokuthobela ngokulula.

Iivalvu ezizenzekelayo kunye neendlela zokupheka ezihlakaniphile zinciphisa impazamo yabasebenzisi, oku kuthetha ukuba izikhalazo zabathengi ezimbalwa kunye nokuhanjiswa okuthe gqolo.

Ubisi lwekhokhonathi kunye namanzi anemingcipheko ekhethekileyo.

Zithwala ii-enzymes zendalo kunye namafutha awonakala ngokukhawuleza xa eshushu ngokungafaniyo.

I-Viscosity itshintsha ngokukhawuleza kunye nokushisa, ngoko ke, ukuba ukuqhutyelwa kwexesha elide, izinto eziluhlaza kufuneka zipholile ngokukhawuleza kwaye zigcinwe kumaqondo okushisa aphantsi ukuze kugwenywe i-rancidity ebangelwa ukuqhutyelwa kwexesha elide.

Lo mgca wemveliso yemizi-mveliso usebenzisa i-homogenizer ukuqinisekisa ukuhanjiswa ngokulinganayo kwamafutha obisi lwekhokhonathi.

I-Adopt Vacuum de-aeration isusa amaqamza omoya abangela ioxidation kunye nokulahleka kwencasa.

Yamkela i-Tubular UHT Sterilizer ukuqinisekisa ukuvalwa okusebenzayo kweemveliso

Itanki nganye ineebhola zokutshiza ze-CIP zokubulala iintsholongwane kwaye zisuse intsalela yamafutha emva kwemveliso.

Isiphumo sisiphumo esicocekileyo, esingaguqukiyo esigcina umbala omhlophe wekhokhonathi kunye nevumba elitsha.

Qala ngesiphumo sakho ekujoliswe kuko.

Ngokomzekelo, i-8 yeyure shift kwi-6,000 L / h ihambisa i-≈48 iitoni zobisi lwekakhukhunathi ngosuku.

Khetha umthamo wesixhobo sokuhambelana nobungakanani bemarike yakho kunye nomxube we-SKU.

Iiparamitha eziphambili ziquka:

• Indawo yokudlulisa ubushushu kunye noluhlu lwesifunxa kwisibulali-ntsholongwane.

• Uhlobo lwe-agitator (uhlobo lwe-scraper kwimigca yekhrimu; i-high-chear yobisi).

• Iidayamitha zemibhobho kunye nee-valve ezininzi ezixhasa i-CIP ezenzekelayo kunye nokutshintsha ngokukhawuleza.

• Indlela yokuzalisa (ibhegi ye-aseptic, ibhotile yeglasi, i-can, okanye i-PET).

Sicebisa uqinisekiso lokulinga phambi koyilo lokugqibela lokuqinisekisa ibhalansi yobushushu kunye nesivuno.

Iinjineli zethu emva koko zilinganisa inkqubo ukuya kuthi ga kwishishini lakho kunye nesicwangciso esiluncedo.

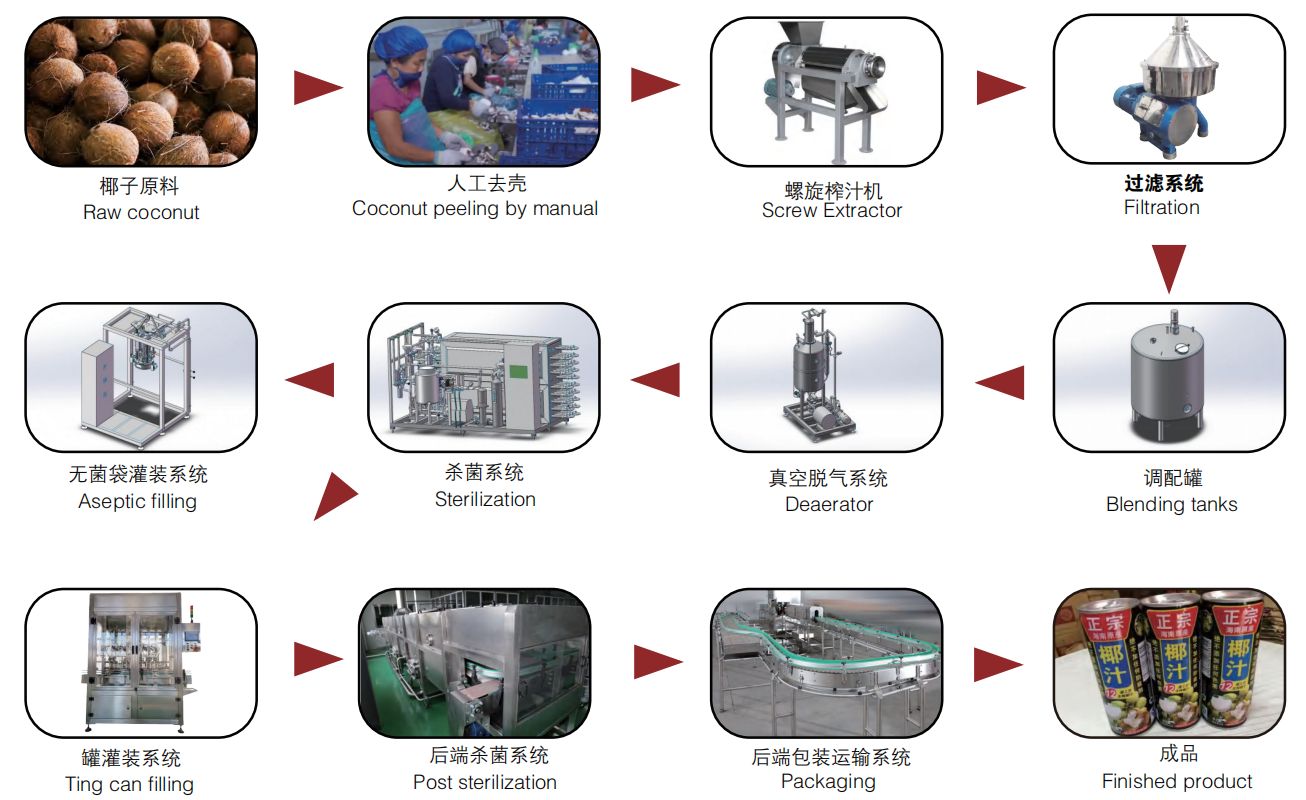

1. Ukungeniswa okukrwada kunye noHlelo

Abasebenzi balayisha iikhokhonathi ezisusiweyo kwibhanti lokutyisa.

2. Ukuqhekeka kunye nokuqokelelwa kwamanzi

Umatshini wokugaya uvula imingxuma kwiikhokhonathi ukukhupha amanzi kwaye uqokelele kwitanki yokugcina ukuphepha uthuli.

3. I-Kernel Peeling kunye neWashing

Inyama yekhokhonathi iyaxotyulwa, ihlanjwe ize ihlolwe amabala amdaka ukuze igcine umbala wayo wendalo omhlophe.

4. Ukusila nokucofa

Iinqwelo ezihamba ngesantya esiphezulu zityumza i-pulp zibe ngamancinci amancinci, kwaye umatshini wokushicilela umatshini ukhupha isiseko sobisi lwekakhukhunathi.

5. Ukuhluzwa kunye nokulungelelanisa

Izihluzi zisusa imicu kunye nezinto eziqinileyo. Abaqhubi bahlengahlengisa isiqulatho samafutha ngokwemigaqo yemveliso.

6. I-Homogenization kunye ne-De-aeration

Ubisi ludlula kwi-homogenizer ephezulu yoxinzelelo kunye ne-vacuum deaerator ukuzinzisa ukuthungwa nokususa umoya. Ezi yunithi zinokudityaniswa kumgca kunye ne-sterilizer ye-homogenization eqhubekayo kunye ne-degassing.

7. Ukuvala inzala

Izibulali-ntsholongwane ze-tubular zifudumeza ubisi ukuya kwi-142 °C imizuzwana emi-2-4 (UHT). I-tube-in-tube sterilizers iphatha imigca yekhrimu enamafutha aphezulu kunye ne-viscosity ephezulu.

8. Ukuzalisa

Imveliso iphola ukuya kwi-25-30 °C kwaye izaliswe kusetyenziswa isithambiso se-aseptic.

9. CIP kunye noTshintsho

Emva kwebhetshi nganye, inkqubo iqhuba umjikelo we-CIP ngokuzenzekelayo nge-alkaline kunye ne-asidi rinses ukugcina ucoceko kunye nokunciphisa ixesha lokuphumla.

10. Ukuhlolwa kokugqibela kunye nokuPakisha

I-inline viscosity kunye neemitha ze-Brix ziqinisekisa ukungaguquguquki phambi kokufakwa kweekhathoni kunye ne-palletizing.

Inkqubo engundoqo efanayo iyasebenza kwimigca yokuvelisa amanzi kakhukhunathi, kunye nohlengahlengiso oluncinci kwibakala lokucoca kunye nobushushu bokwenza inzala ukugcina i-electrolyte yendalo.

1. Umatshini wokugaya iCoconut kunye noMqokeleli waManzi

Umatshini wokugrumba ugrumba umngxuma omncinci kuphela kwikhokhonathi, ugcine zombini amanzi kunye nekernel zichanekile kangangoko kunokwenzeka.

Umjelo wentsimbi engenasici uqokelela amanzi ekhokhonathi phantsi kwesiciko esivaliweyo ukuze kuthintelwe iintsholongwane okanye uthuli.

Eli nyathelo likhusela incasa yendalo phambi kokukhutshwa okuphambili.

2. Icandelo leCoconut Milk Extraction

Eli candelo lidibanisa i-grinder kunye ne-juice screw presser.

Iqhekeza inyama yekhokhonathi ibe ngamasuntswana amancinci kwaye isebenzisa i-screw presser ukukhama ubisi lwekhokhonathi.

Xa kuthelekiswa noshicilelo lwezandla, iphucula imveliso ngaphezu kwe-30% kwaye igcina amanqanaba amanqatha ahambelanayo.

3. Inkqubo yoHlulo kunye ne-Centrifuge ye-Coconut Water

Isihluzi esinamanqanaba amabini e-mesh sisusa imicu emikhulu emanzini ekhokhonathi.

Emva koko, i-disc centrifuge ihlukanisa amaqhekeza amanzi, ioli ekhanyayo, kunye nokungcola.

Olu lwahlulo luphucula ukucaca kwemveliso yamanzi yekhokhonathi.

4. Homogenizer

Umatshini wokucubungula ubisi lwekakhukhunathi uquka i-homogenizer ephezulu yoxinzelelo lokuzinzisa i-emulsion.

Kwixinzelelo lwe-MPa ye-40, iphula iiglobhu zamanqatha zibe ngamancinci amancinci.

Ubisi luhlala lugudile kwaye aluhlukani ngexesha lokugcinwa.

Eli nyathelo lingundoqo ukuzinza kweshelufu kwiziselo zekhokhonathi.

5. UHT Sterilizer

Ukukhetha i-sterilizer ye-tubular okanye i-tube-in-tube sterilizer ixhomekeke kwi-fluidity yemveliso.

Amanzi ekhokhonathi afuna ubushushu obuthambileyo ukuze agcine ivumba; i-coconut cream idinga ukufudumeza ngokukhawuleza ukuphepha ukutshisa.

Ulawulo lwe-PLC lugcina ubushushu ngaphakathi ± 1 °C kwindawo yokubeka.

Uyilo lokubuyisela amandla kwi-sterilizer ye-tubular inceda abathengi ukunciphisa iindleko zokusebenza.

6. Umatshini wokuzalisa i-Aseptic

Umatshini wokucoca amanzi kakhukhunathi ugqiba ngenkqubo yokugcwalisa oyinyumba.

Zonke iindlela zemveliso zenziwe nge-SUS304 okanye i-SUS316L yensimbi engenasici.

Inokusebenza kunye nesibulala-ntsholongwane kunye ukuqonda i-CIP engaphakathi kunye ne-SIP.

Oku kuqinisekisa ubomi beshelufu obude ngaphandle kwezithinteli.

7. Inkqubo yokucoca i-CIP

I-automated CIP skid ixuba amanzi, i-alkali, kunye ne-asidi ukucoca iitanki kunye nemibhobho.

Iqhuba imijikelo echaziweyo ngokuqukuqela, ixesha, kunye nolawulo lobushushu.

Abasebenzisi bakhetha iiresiphi kwi-HMI kwaye babone inkqubela yexesha lokwenyani.

Le nkqubo inciphisa ixesha lokucoca nge-40% kwaye igcina yonke i-coconut processing machine ilungele ibhetshi elandelayo.

Iifektri zinokuqhuba imithombo eyahlukeneyo yekhokhonathi ngaphandle kokutshintsha umgca oyintloko.

Iikhokhonathi ezintsha, ezikhenkcezisiweyo, okanye ezicutshungulwe kancinci zonke zilingana necandelo lokulungiselela elinye.

Izinzwa zilungisa isantya kunye nokufudumeza ukuze zitshatise izinto eziqinileyo kunye nomxholo we-oyile.

Ungaqhuba kwakhona iintlobo ezininzi zemveliso:

• Amanzi acocekileyo ekhokhonathi kwi-PET, iglasi, okanye i-tetra-pack.

• Ubisi lwekhokhonathi kunye nekhrimu yokupheka okanye izimuncumuncu.

• Isiseko esigxininisiweyo sekhokhonathi ukuze kubunjwe ngokutsha kwiimarike zokuthumela ngaphandle.

• Iziselo ezixutywe nejusi yeziqhamo okanye iprotein yezityalo.

Ufakelo olukhawulezayo lokutshintsha kunye neendlela ezizenzekelayo zevalvu zinciphisa ixesha lokuphumla ngexesha lokutshintsha kwe-SKU.

Olo bhetyebhetye lunceda izityalo ukuba zihlangabezane nemfuno yamaxesha onyaka kunye nokuphucula ukusetyenziswa kwemveliso.

Inkqubo ye-PLC kunye ne-HMI yenza ingqondo yomgca wonke.

Abasebenzisi banokulayisha iiresiphi ezichazwe kwangaphambili zobisi okanye iimveliso zamanzi kwaye babeke iliso kwitanki nganye kunye nempompo ngexesha lokwenyani.

Iimpawu ze-Smart ziquka:

• Isikrini esichukumisayo esisembindini esineegrafu zentsingiselo kunye nedatha yebhetshi.

• Ufikelelo olusekwe kwindima kubaqhubi, abaphathi, nabasebenzi bolondolozo.

• Ikhonkco le-Ethernet lokubekwa esweni okude kunye nenkxaso yenkonzo.

• Ukulandelela ukusetyenziswa kwamandla kunye namanzi kwibhetshi nganye.

Ukudibanisa okuzenzekelayo kugcina izenzo ezingakhuselekanga ekusebenzeni, ezikhusela zombini imveliso kunye nezixhobo.

Umgca uhlala uzinzile kuzo zonke iishifti, nokuba kukho uqeqesho olulinganiselweyo lwabaqhubi.

I-EasyReal ixhasa iprojekthi yakho ukusuka kwingqikelelo ukuya ekugunyazisweni.

Iqela lethu lifunda ifomula yemveliso yakho, ukupakishwa, kunye noyilo oluluncedo ukuyila inkqubo elungeleleneyo.

Siyazisa:

• uyilo kunye noyilo lweP&ID.

• Ubonelelo lwezixhobo, ukufakwa, kunye nokugunyaziswa kwisiza.

• Uqeqesho lomsebenzisi, iindawo ezisecaleni, kunye nenkonzo ekude ngexesha lakho lokuqala lemveliso.

Isityalo ngasinye sokulungisa ubisi lwekhokhonathi silandela imigangatho yococeko yamazwe ngamazwe kunye nokhuseleko, kunye neziqinisekiso ze-CE kunye ne-ISO.

Iifektri zaseAsia, eAfrika, naseLatin America sele ziqhuba imigca ye-EasyReal evelisa amawaka eelitha ngeyure yobisi lwekakhukhunathi kunye namanzi imihla ngemihla.

Qhagamshelana nathi ukuxoxa ngomthamo ojolise kuwo kunye nesimbo sokupakisha.

Siza kukunceda uqwalasele umatshini wokusetyenzwa kwekhokhonathi ukukala imveliso yakho ngokufanelekileyo.