Multi Effect Falling Film Evaporator

The evaporator spreads feed into a uniform film inside vertical tubes. Vacuum lowers the boiling point, so evaporation happens gently at modest ΔT while the film moves quickly. That thermal logic preserves sensitive ingredients and limits fouling.

Multi effect layout routes secondary vapor from one effect to heat the next at lower pressure, which raises steam economy and reduces boiler demand.

Plants can further add TVR (steam jet thermocompressor) or MVR (mechanical recompressor) to recycle vapor instead of burning extra fuel. The frame, piping, and vessels use stainless steel contact surfaces with sanitary design.

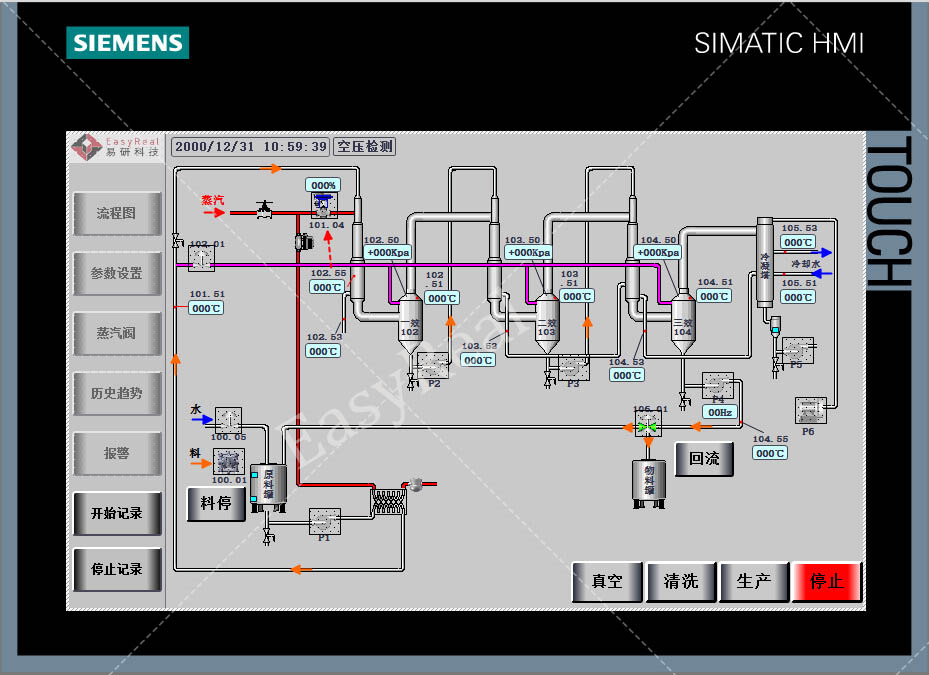

The control system is Siemens based with HMI trends, interlocks, and recipe handling; operators see setpoints on screen and keep runs repeatable across shifts.

Food and beverage producers concentrate clear and cloudy juices, pulps, syrups, dairy streams, coffee and plant extracts while holding high quality.

Vacuum + short residence reduces “cooked” notes and color loss, which improves downstream sensory results and dryer yields.

Chemical and pharma intermediates benefit from low thermal stress and stable vacuum control.

Gentle ΔT under vacuum matters for uptime and quality. Aroma compounds flash if pressure runs high; vacuum protects them and reduces stripping losses.

Hygiene rules demand smooth stainless steel contact surfaces and automated CIP cycles with logged parameters.

This industrial design gives operators clear setpoints and interlocks so they focus on throughput and compliance rather than fighting drifts.

1. Feed reception & screening → stabilize solids, remove large particulates.

2. Preheating → raise feed to approach temperature for stable film formation.

3. Vacuum set & condenser check → pull target pressure; verify cooling capacity.

4. Film distribution → wet all tubes uniformly; protect U value and flavor.

5. Effect 1 evaporation → boil off water; route vapor to heat the next effect.

6. Inter effect vapor transfer → cascade to lower pressure; recycle latent heat.

7. Effect N evaporation → finish concentration at the gentlest feasible ΔT.

8. Vapor liquid separation → remove entrainment; protect condenser and aroma.

9. Condensation & condensate handling → return clean condensate to headers.

10. Product to hold tank / next unit → tie to UHT, deaerator, or aseptic filler.

11. CIP → run rinse/alkali/acid/final rinse; log time temperature.

A) Falling Film Body

Structure: vertical tubes with sanitary headers and optimized tube sheet.

Purpose: form a thin, gravity driven film for gentle, rapid evaporation.

Working principle: vacuum depresses boiling point; ΔT stays low; residence time stays short to preserve flavor and color.

Application: juices, pulps, dairy, extracts.

Differentiators: high heat transfer coefficients and short flow through time; hygienic stainless steel contact surfaces.

Impact: high quality, less fouling, steady throughput across long runs.

B) Film Distribution System

Structure: feed distribution head and internal devices that wet each tube evenly.

Purpose: prevent dry wall spots and hot streaks.

Working principle: controlled wetting rate keeps a continuous film across all tubes.

Application: critical on fruit pulps and mixed solids feeds.

Differentiators: even wetting upholds U values and extends run lengths.

Impact: fewer cleaning stops; stable product quality over shifts.

C) Preheater & Multi Effect Heat Exchangers

Structure: preheater plus effect heaters in series.

Purpose: reuse latent heat from the previous effect to reduce steam use.

Working principle: vapor from effect i heats effect i+1 at lower pressure.

Application: triple or quadruple effects as a baseline; more effects where utilities justify.

Differentiators: compatible with TVR/MVR and waste heat sources.

Impact: higher steam economy and lower cost per kilo.

D) Vapor–Liquid Separators

Structure: vertical/vortex separators with demisters.

Purpose: remove droplets before condensers and recompressors.

Working principle: gravity and flow control limit entrainment.

Application: all effects; especially last effect for aroma retention.

Differentiators: cleaner condensate; stable vacuum and compressor loads.

Impact: better equipment life and fewer aroma losses.

E) Surface Condenser & Vacuum Environment

Structure: shell and tube condenser, cooling water loop, vacuum pumps/ejectors.

Purpose: convert vapor to condensate and keep vacuum on target.

Working principle: heat rejection at stable approach temperature stabilizes pressure.

Application: food, dairy, chemicals; deep vacuum for heat sensitive feeds.

Differentiators: steady vacuum improves product quality and energy balance.

Impact: fewer alarms; consistent runs at target temperatures.

F) TVR (Thermal Vapor Recompression) Module

Structure: steam jet ejector (no moving parts) with motive steam control.

Purpose: recompress a vapor slipstream and feed it back as heating medium.

Working principle: motive steam entrains secondary vapor and lifts its temperature/pressure.

Application: when steam is available and CAPEX must stay moderate.

Differentiators: simplicity and reliability “like adding an extra effect.”

Impact: strong OPEX savings vs. classical trains.

G) MVR (Mechanical Vapor Recompression) Module

Structure: blower/compressor, motor drive, VFD, condensate management.

Purpose: recompress most vapor with electricity instead of live steam.

Working principle: mechanical work raises saturation temperature for reuse as the primary heater.

Application: electricity friendly sites or decarbonization projects.

Differentiators: lowest specific steam demand; reduces fossil fuel exposure.

Impact: major energy and CO₂ cuts with stable thermal profiles.

H) PLC + HMI & Automated CIP

Structure: Siemens PLC, touchscreen HMI, top brand electricals, recipe handling, interlocks; integrated CIP function and valves.

Purpose: maintain setpoints, show trends, and shorten changeovers with automated CIP cycles.

Working principle: closed loop control on temperature, levels, vacuum, and flows; three working modes available for effect combinations.

Differentiators: independent Siemens control, linkage control for safe state transitions, and international brand components.

Impact: fewer operators per line, safer transitions, and clean, repeatable runs.

Run clear/cloudy juices, pulps, dairy concentrates, plant extracts, and syrups on industrial schedules. The falling film protects quality under vacuum.

Engineering can align effects, vacuum, and heat integration across the full train.

Plants can route concentrate to UHT, deaeration, or aseptic filling with short lines to limit losses and keep audits simple.

Operators manage PLC recipes, setpoints, and alarms from HMI screens, while interlocks coordinate pumps, valves, and vacuum so startups and stops stay safe. The system logs trends and batch records for QA and plant reviews; data exports support continuous improvement.

EASYREAL’s design uses Siemens controls and branded electrical components for reliability.

The evaporator supports three operating modes (e.g., all effects together, 3rd + 1st, or 1st only) so plants can adapt to raw material swings, tariff windows, or partial load operation without losing stability.

CIP runs from the same HMI with defined steps and temperature/time checks.

Share your feed window (inlet/outlet °Brix or solids, viscosity), daily water removal load, allowable product temperature, and utilities (steam grade/costs, power, cooling water).

We will propose effect count, TVR/MVR options, heat integration opportunities, and a layout/P&ID with commissioning steps and a spares plan.

Contact EASYREAL: sales@easyreal.cn.